Hey all. I have a 1996 GMC K1500 5.7V8 Vortec Engine. I am getting the P1345 code...

...I keep reading that you want the timing to be within +-2 degrees of 0. Is this right? I do have the manual but I cant find this spec in there. I may just not be looking in the correct area.

Is this +- 2 Degree at idle or 1100 RPM or 1500 RPM? I have read conflicting statements on this.

Greetings IMV8N,

Welcome to the GMT400 forum!

As part of meeting the stricter '96 emissions, GM switched from the TBI 5.7 to the

new Vortec 5.7. Why do you care? Well, for the first 40 years ('55 to '95) the way

you adjusted the base ignition timing was to rotate the distributor with respect to the

camshaft that drove it, which in turn was synced to the crankshaft via the timing chain.

Starting in '96, the base ignition timing is taken directly from the front of the crankshaft

via the output signal from the

CKP (CranK Position) sensor to the VCM. The distributor

is *not* involved at this stage of the process!

In turn, the VCM subsequently computes the optimum spark advance or retard, sends a

5v trigger back to the ICM>Coil>Distributor, and via this signal path the trigger is

transformed into a multi-KV spark.

This spark proceeds to arc from spinning rotor tip to the nearest terminal on the distributor

cap, and down the associated spark plug wire to the waiting plug. (Please keep that

rotor tip<>terminal arc in mind when we discuss adjusting the distributor position later on.)

In English, starting in '96, twisting the distributor clockwise/counterclockwise does

not change the base timing. (!) But for a couple of important reasons I'll get into

in a bit, we still need to get the distributor housing precisely set so that we don't

get the P1345 code.

****

To answer your question about the specs, I first went to the '96 Factory Service Manual,

and I scoured it, both distributor installation & P1345 troubleshooting section, but try as I

might I couldn't find it either? Instead of a spec, the manual's focus seemed on lining

everything up to the marks indicated in the drawings. But I know I've read the specs

somewhere?

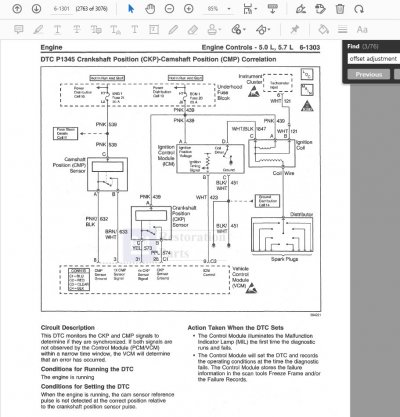

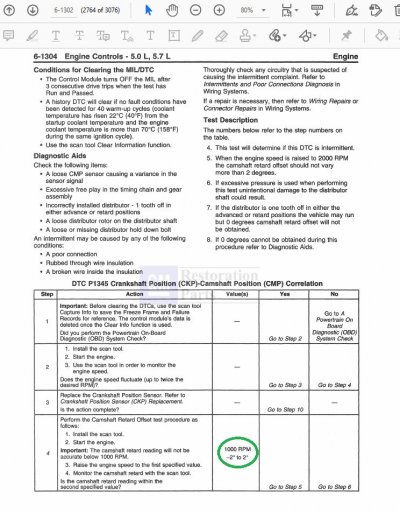

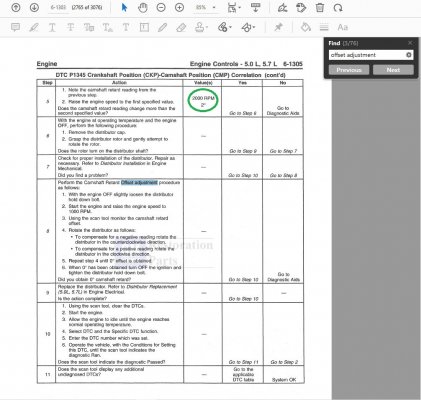

So I went to the '99 FSM, and in the P1345 troubleshooting section (Vol 2, pp. 2763-2765)

the whole procedure is listed,

including the specs that you have been looking for.

(See the 3 attachments below.)

I recently bought a cheap ODBII scanner. It provides a reading for: "Timing Advance for #1 cylinder" which is coming back at -24.0 degrees. Does Timing Advance for #1 cylinder also mean CMP Retard? If these are two different items/readings, can I use this reading to set my timing?

My plan this weekend is to buy a timing light. Set my engine at TDC for #1 cylinder. Check the distributor rotor to ensure its pointing at the number 1 cylinder in the distributor cap. Loosen the distributor hold down bracket/bolt. Use timing light while turning distributor to try and get timing to as close to zero as possible. I also bought a new camshaft and crankshaft postion sensor. So all else fails I will replace those items.

Does this sound correct in as far as the recommended troubleshooting steps? Am I missing anything? Any other recommendations? Thank you in advance for any information.

OK, this section of your original posting is why I went into the whole '55-'95 pre-Vortec

vs '96+ Vortec 'where does base timing come from' above.

In the perfect world:

* we have a stretch-free timing chain

* There is no wear in the gears between the cam & distributor.

* The Vortec distributor is unworn, no loose parts, and the 13-tooth gear

is not installed 180° out of phase. (Making it impossible to hit the 0° adjustment. (!)

In this scenario, all we do is loosen the distributor hold down, the scan tool

tells us how close to perfectly synchronized the CKP and CMP sensors are, and

we dial it in for 0°. And by doing so, this gives us:

* The *minimum* distance that the spark has to jump from rotor tip to

the correct spark plug wire terminal. If you visualize rotating the distributor

housing (and cap) away from zero degrees, you can see how a misalignment

could lengthen the distance the arc has to travel. Shortest is bestest. :0)

* Properly synced CMP and CKP sensors allows the Sequential Multi-Port

Fuel Injection to work as advertised. (The CMP sensor is what allows the

computer to know where the engine is in the firing order, so it can figure

out the proper fuel injector sequencing.) I'm not positive what the threshold

is, but if all this gets out of sync, I think that it maybe leads to injector batch-mode

operation?

* If the CMP & CKP signals aren't synced up, I *think* that this can lead to

the computer goofing the reporting of which cylinder was the one suffering

from a misfire, etc.

So how about the real world?

First of all, some folks have had difficulty in getting the P1345 code to

clear. Here are some popular reasons why:

1) Excess wear between the distributor and camshaft gears. Note that

it takes nothing to spin the rotor, but since the oil pump is driven off

the other end of the distributor shaft, there can be a significant load

placed on these gears. (High revs on a cold motor with thick oil, etc.)

A quick search of the forum will describe ignition issues traced back

to these gears being worn/excess play/etc.

2) Timing chain with excess wear/slack in it. If it's bad enough, it

can cause sync issues at certain speeds/harmonics. In general terms,

the more wear, the more the camshaft (& distributor) falls behind the

crankshaft. I have read in here somewhere that at least one member

was able to extinguish a P1345 Check Engine light by adjusting the

distributor to +2° at 1000 rpm instead of 0°. (Attempting to counter

the timing skew from normal wear.) Note that the FSM procedure has

you adjust the timing at 1000 rpm, and then check to see how much

the setting drifts at 2000 rpm. Makes sense.

EDIT: Mechanics who are looking for 'end-to-end' confirmation that they

have a robust physical interconnect between the front of the crank and

the distributor shaft will take advantage of the availability of this CMP<>CKP

correlation signal to look at how little overall 'slop/scatter' is observed.

(Just like old-school mechanics would observe just how steady

the spark timing was at various speeds with their timing lights.

On a fresh motor with quality parts the timing did vary with rpm

and vacuum changes, but did so smoothly.

On a worn out motor {loose timing chain, worn mechanical

advance pivot points, excess distributor shaft bushing wear, worn

distributor/cam drive gears, etc} ...the timing would adjust, but

the entire time the spark timing would be very jumpy/jiggly/hard to

read. This was often referred to as spark scatter.)

...but I digress. On a fresh Vortec rebuild, no doubt that this cam/crank

correlation signal is super steady. But on an 350,000 mile truck that you are

trying to revive after it's been sitting in someone else's back yard, this

signal might be jumping in & out of specification. Unfortunately, for

99% of the folks out there, no P1345 after rebuild = they never see what

a good sync signal looks like for comparison purposes.

As you can see, if I'm given some signal I can look at, I'm always

wondering if I can somehow (mis)use that same signal in order to get

a further glimpse into the engine's overall health?

3) Anything that's loose/worn inside the distributor can affect this adjustment.

But that's well covered elsewhere, so I won't elaborate here.

4) EDIT: Thanks to relaxed QA inspections at some new/reman operations,

the memo about how there's only ONE correct 'clocking before pinning'

orientation of the 13-tooth distributor (driven) gear isn't taught to the

assemblers, or verified after the fact before shipment.

And the way that this is discovered is when the mechanic can't rotate the

distributor housing far enough to get the 0° reading within the tight

confines that the distributor operates in at the rear of the engine.

So the mechanic figures the distributor installation is off a tooth, pulls it,

reclocks the oil pump drive with a long screwdriver ever so slightly to

allow the 1-tooth adjustment, stuffs it, and now after all that the reading

is now too far in the

other direction? WTF? (Why The Face? :0)

This is where you will find threads where, after mucho frustration,

the distributor is either pulled, and using a pin punch, the assembly

error is undone, or the faulty distributor is replaced under warranty.

(And hopefully it was just a one-off vs. a whole batch put together

180° out...and the same thing happens again?)

Anyway, most folks will never see this, so just keep in the back of your

mind that this

is possible and allow the CMP scan tool reading steer you down

the correct repair path.

****

Apologies for the length. And the fact that you may need to read through all of

this twice before it makes any sense. Plus the reality that some of this might

overlap with east302's & Schurkey's comments...since they beat me to this.

But my goal is that somewhere in all this a newcomer to the Vortec ignition setup

can now reason through whatever it takes to successfully clear the code. Driving

around with a P1345 code doesn't allow you and your engine to take full advantage

of what the VCM can deliver.

Best of luck. And we look forward to you posting what you find.

Cheers -