now this here is by far the best and biggest help ive seen for setting these dist. thank you, good sir. as luck would have it, apperently i muffed up somehow. im throwing the 1345 also, did the process of turning the dist one tooth, and yet im stuck. as the truck runs, and the rotor points *just* before cyl1 at TDC. cam retard shows 20*. i retard one tooth, and at the same cap position the cam retard shows -28*

Greetings drifterwanb666,

Glad you found my explanation helpful. My target audience are those who are both

new to the GMT400 hobby and also wish to learn how to be a more self-sufficient

DIY owner. Thanks for the positive feedback, it's appreciated.

****

Before performing any of the following, please make sure that you have already tried to

rotate the distributor per the info in @east302's reply above (#10) and you can't get

the CMP measurement to 0° before the distributor is prevented from turning any further

due to physical interference.

****

OK then. If you are reading this I'm assuming that you find yourself stuck just like many others

have also been. BTW, good job with your clear description of the distributor phasing issue

that you are experiencing.

The problem description is:

Installed distributor is showing a +20° offset.

Retard distributor *1* tooth, now -28° offset.

OK. This is a very specific failure footprint. In order for all involved to be able

to reason through how we can fix this, I first need to do a little quick math.

First, in one full revolution of the distributor shaft the rotor travels exactly 360°.

Now here is the trick. If you pull the distributor out & count the number of teeth

on the gear, you should find an odd number: 13. (Take your time, I'll wait here. :0)

Now why do we care? Well, if they had made the tooth count an even number

(ie: 12 or 14) then when the gear was installed onto the distributor shaft, you

would end up with the same relative phasing between gear teeth and shaft no

matter which way the gear was installed.

But with 13 teeth, IF the gear is installed 180° out, then we are going to end up

with one distributor stuffing that's too far positive, and then when we retard it

1 gear & restuff, it's now too far negative?

So how much of an offset are we talking about? Well, 360° divided by 13 teeth

= just shy of 28° per tooth. And again, because we are dealing with an odd

(asymmetric relative to the roll pin) number of teeth, by removing the drive

gear, spinning it 180°, and reinstalling it, we will now have shifted the phasing

by roughly 1/2 a tooth.

And when you reinstall the distributor, now the phasing will be such that you

should be able to physically swing the distributor either positive or negative

as needed for a CMP reading of 0° *before* running out of room to rotate

the distributor assembly.

Here's the illustration in the FSM showing the gear removal/installation:

You must be registered for see images attach

And how does the distributor gear get installed wrong in the first place? We aren't sure,

but as I mentioned in my previous reply it seems that this assembly error is being

missed during the QA process by whoever is making/remanufacturing these distributors.

Another way this happens is during a camshaft change, where the new camshaft is

installed, and at the same time a new (compatible metallurgy) distributor gear is also installed

by the mechanic...but unfortunately they phase it 180° out. Followed by the P1345 code.

Fudge!

****

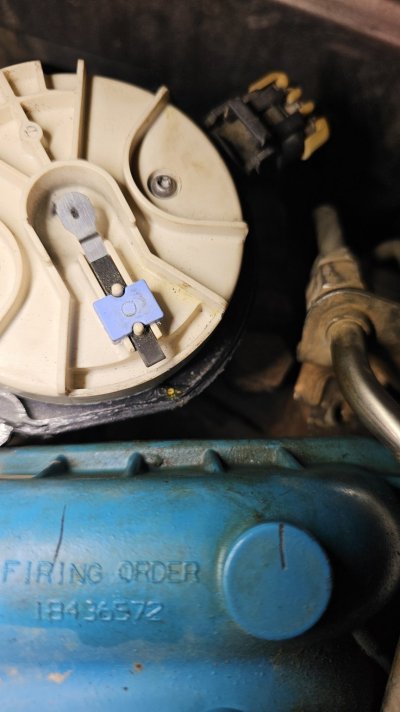

Listen, while we are in here looking for trouble, let's quickly discuss one more issue

having to do with these distributor/cam gears. Simply put, some people pull the

distributor out, and the teeth are worn to almost a knife edge. (Refer to 1st attachment.)

Some people know to look for this, find it, fix it, and away they go. But it's the other

folks who don't know to check this out, don't realize that this is a problem, and put

this back in, and experience all kinds of wiggle-waggle/spark timing scatter/weird

misfires, etc.

Since mom said I'm not supposed to identify a problem without also proposing a

solution, I have included the 2nd attachment showing what a new, spiffy, unworn

distributor gear looks like.

****

And that's a big-picture overview of the most popular issues surrounding the

cam drive/distributor driven gears. IF you get the phasing correct, AND your

gears are not worn, then there should be a near 100% chance of you being

able to adjust the distributor within the tight confines of where it lives.

Hope this shed some light on the misunderstood '96+ Vortec distributor setup,

especially when the CMP<>CKP signals are out of sync, and the distributor

is physically blocked from rotating far enough to make the adjustment.

If you have any follow-on questions about this please don't hesitate to ask.

And not if but when you clear the P1345 fault please report back here with what

it took so that other folks trying to sort out similar issues can benefit from

your experience.

Best of luck --

Attachments

Last edited: