OK, after all the build up in Posts #14 thru #19, it's finally time to take all

that troubleshooting setup and start proving/disproving each part in this

series circuit.

****

When it comes to an electrical series circuit, I'd like to use a simple mechanical analogy:

"A chain is only as strong as it's weakest link."

But before we start troubleshooting, as promised in Post #17, I am going to

emphasize Safety. Why? A: Because we are going to troubleshoot the

starter in a Go / No-Go method. Workie? Or No Workie?

In English, we are going to jumper battery voltage to the starter solenoid. And ever

since the Clutch Safety Switch was mandated ~50 years ago, people no longer realize

that an engine can be started in gear, and mayhem can occur, especially when nobody

is behind the wheel. (!)

Given this, before we proceed, YOU SHOULD:

1) ENSURE that the transmission is in Neutral.

2) The Parking Brake is fully applied. And Chock the wheels. (Chocks are cheap money at Harbor Freight.)

3) NOBODY (including YOU) are in front of or behind the truck.

4) DO NOT do this while under the vehicle, or standing on your head under the dash.

NOTE: If you can involve a friend, then have them apply the brakes firmly during testing.

Bottom line, simply be smart, and you will be fine.

****

Troubleshooters will refer to this method as a Binary Search. Others call this a half-split method.

Purists like to eliminate as much as possible per test. But I simply recommend that you test

in whatever sequence that gives YOU the most confidence in your diagnosis.

Step #1: Let's prove that the starter & starter solenoid are good.

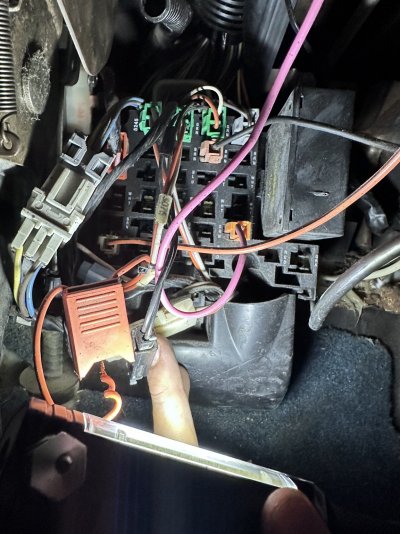

* With the truck SAFED, disconnect the purple wire from the starter solenoid. Connect one end

of the fused-protected jumper wire where the purple wire was connected, make sure that you are

out of the way, and apply battery voltage to the other end of the jumper.

* Starter spins over? Starter good. Do it 2 or 3 times -- make sure the first success wasn't a fluke.

* Starter stays silent? Recheck the big current connections. Then pull the starter and have it tested

for free at the nearby auto parts store. Keep working Step #1 until when you jumper battery voltage

to the starter solenoid that the engine

always spins over.

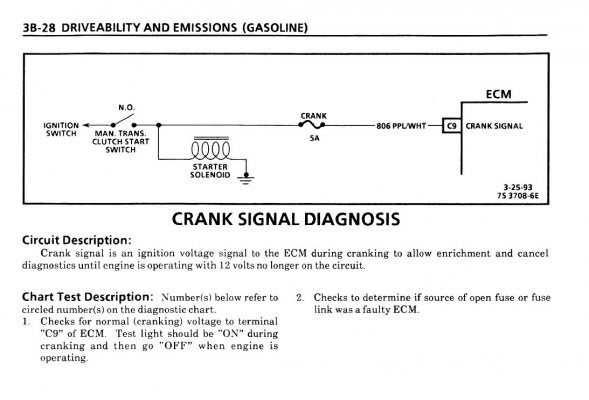

Step #2: Troubleshooting the Control Circuit:

* Now that the starter/starter solenoid combo is tested good, reconnect the purple wire to the starter

solenoid & attempt to start the truck normally. Now engine turns over on command? Great. Done.

* Truck still doesn't start? Now what we are going to do is use our fused jumper to apply power to

our control circuit, eliminating one link of the chain after another. (refer to that diagram I drew in Post #

16.)

For example, I could connect the jumper to pin #5 on the Clutch Start (Safety) Switch, depress the clutch

pedal, and then apply battery voltage to the other end. (Note: A helper would make this a lot easier.)

* IF the starter now spins, then the clutch switch has continuity, and we need to look upstream at the

Ignition Switch. And you keep going back until you find the open in the circuit. (PO's Kill Switch? Other

damage to the harness? Etc.)

****

Anyway, that's my take on this. The beauty of Step #1 is that we not only prove that the starter/starter solenoid

is good, but we also prove the high current side of the equation. AND in addition we prove that our test setup

is valid & can be relied upon. I find that once I can *make* the starter spin on my command, then I gain the

confidence that I'm going to figure this out. And ultimately, that's all a troubleshooter really needs, is that

they can narrow down the failure to something that can be repaired or replaced.

****

The funny thing is that once you start the divide & conquer troubleshooting process, it will probably take

you less time to perform these tests than it did to wade through all this blah blah blah.

Unfortunately, when it comes to troubleshooting a circuit with several parts, each part relying on the

previous section(s) feeding it, you kinda have to know everything before you can figure out anything.

And maybe this helps to explain why people who troubleshoot electrical stuff are just a little off of the

beaten path, if you know what I mean? And I've met crackerjack mechanics who could really swing a

wrench, but at the same time wanted nothing to do with electrical stuff. And I've also worked with

electronic wizards who couldn't install a serpentine belt to save their lives. But IMHO somewhere in

the middle of those 2 extremes is where you want to end up.

And outlasting this "No Crank" issue will be a great step towards that goal.

Let us know what you find. And please be SAFE while you are busy finding it.

Thank you.