dwragon

OBS Enthusiast

Hi all, OK, so the frame cracked at the drivers t on my 94 K3500. I had on standby a 92 C3500 that I knew had fuel issues. I replaced the one inch tube above the fuel pump, filter, sock and cleaned the tank. I drove the truck for over a week with no problems on the farm, then headed to town 45 miles away. It acted like the cat was clogging up, so I stopped at a friends and removed it as it was behind the muffler, and welded a temporary pipe splice inline.

After that I went to start the truck and it would not start. I installed a new fuel pump assembly with strainer sock. The truck started up without any problems, then died after 30 to 60 seconds of running, when idling down to 1000 RPM. I drove it to the local parts store and replaced just about everything electronic on the engine (Ignition module, fuel relay, IAC, MAP, so on that could cause an engine shut off, with no change.

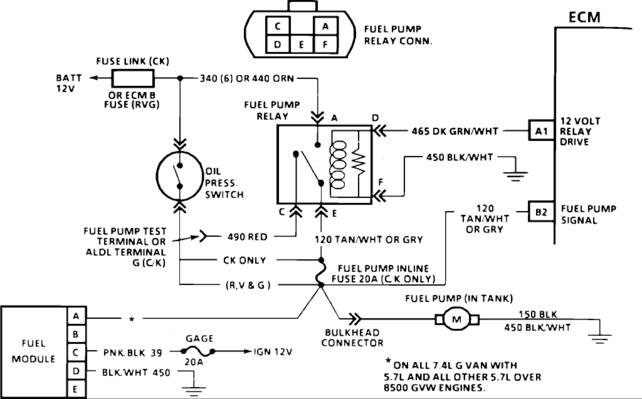

The Chilton's wiring diagram for 88-98 C/K series shows a "Hot Fuel Module", (also called a fuel pump driver) or control module. I found mine behind the glove box. When I disconnected this module, the truck did not run. The fuel pump control modules regulate the voltage supply to the electric fuel pump. These modules receive an electronic signal from the engine control module that determines the voltage applied to the pump, altering pump motor speed and pressure. This is about the only thing I have not replaced, and while it seems to operate properly, it may be shutting off the fuel after the 30 to 60 seconds if it is defective.

If anyone has had the same problem I would appreciate knowing how you cured it, or if/how it can be bypassed.

After that I went to start the truck and it would not start. I installed a new fuel pump assembly with strainer sock. The truck started up without any problems, then died after 30 to 60 seconds of running, when idling down to 1000 RPM. I drove it to the local parts store and replaced just about everything electronic on the engine (Ignition module, fuel relay, IAC, MAP, so on that could cause an engine shut off, with no change.

The Chilton's wiring diagram for 88-98 C/K series shows a "Hot Fuel Module", (also called a fuel pump driver) or control module. I found mine behind the glove box. When I disconnected this module, the truck did not run. The fuel pump control modules regulate the voltage supply to the electric fuel pump. These modules receive an electronic signal from the engine control module that determines the voltage applied to the pump, altering pump motor speed and pressure. This is about the only thing I have not replaced, and while it seems to operate properly, it may be shutting off the fuel after the 30 to 60 seconds if it is defective.

If anyone has had the same problem I would appreciate knowing how you cured it, or if/how it can be bypassed.

Last edited: