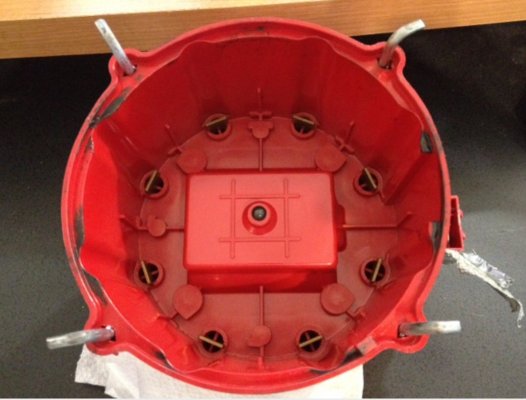

Well boys add the above picture of the dizzy cap to a list of signs of failure. Slapped the new dizzy cap and rotor on the truck this morning and she started right up easy.

*YES*

I only ran it for a few minutes because I still need to change the oil.

In 5 years of owning this thing I’ve changed the cap and rotor at least 6 times. I think it’s time to get a higher quality one lol.

With 20/20 hindsight, I think the pinnacle of small block distributors were the

large cap HEI units. This upgrade to the original points/condenser dizzys

occurred right around the time that catalytic converters were introduced

for the '75 model year. (See attached for a pic of the huge high voltage playing

field that the old HEI distributor caps had to work with.)

The GM engineers wanted big spark gaps and a system that would reliably fire

them -- otherwise, the expensive cats would melt down during the warranty

period, and that would be bad juju.

I can personally vouch for the fact that the then-new HEI systems had the suds.

(Previously I had been bit by bad spark plug wires on old points systems, and it was

always a shock...but the *one* time I got shocked by a HEI system, it felt like

a mule had kicked me in the arm. (!) From that point on I wouldn't touch an HEI

wire unless the engine was off. Life Lesson learned. :0)

When the old big cap HEI systems were replaced with the newer crab-cap jobs, it did

make the ignition wire dressing much neater. But that's on the outside. On

the inside of the HEI's big cap, there is plenty of real estate between the individual

cylinders. And the high voltage path from rotor tip to *every* individual spark plug

wire is short, sweet, straight up & out.

And thanks to the inverse-squared law, every time you double the distance between

2 electrical terminals, you end up with 1/4 as much stress on the insulator between

them. (Oversimplification, but when high voltage is concerned, more space is more better.)

On the other hand, due to the design of the new crab cap (featuring spark plug wires

sorted out to Left and Right banks) we now have a high voltage path running

across the inside of the cap? And as your photo clearly shows, the insulator

material that the cap was made of failed, allowing the #3 cylinder spark plug to see

some/all of the 8 sparks for every cam revolution?

And if one of those sparks occurred while the intake valve was open, then it would certainly

fire both the cylinder AND also back through the intake manifold?

Plain & simple, the only 2 realistic solutions to this design issue are to A) someone has to

sell a Vortec distributor cap with superior high voltage insulator material, or B) some

entrepreneur needs to design an old-school sequentially-wired distributor cap

that can be retrofit on top of the Vortec distributor base? There's no reason that

this can't be done that I can see? Sure, you would need custom-length wires, but

I would be the first in line to try one out?

In English, I think that when the Vortec crab cap designers attempted to improve

how the spark plug wires were routed to the original distributor caps, they

created a new problem. The layout of the new Vortec crab cap design puts a greater

stress on the high voltage insulator material that the cap is made from?

Now to start driving it and see how she runs and if the rough idle and cylinder 4 misfire are gone. Thanks for your guys help and support !

Fingers crossed that the exploratory intake manifold gasket renewal + the

discovery/replacement of the bad cap will be just enough to allow the engine

to run as designed.

But don't forget to get that cooling system flushed at your earliest opportunity.

And if that P0304 comes back after the cooling system flush then the only thing

left is the valve stems being too tight in the valve guides while climbing a grade

as described in that old TSB.

Let us know what happens. And thanks for keeping us in the loop like you have been.

Misfire-free travels!

Cheers --