2-page TSB from REMY starters --- about upgrading from old heavy 10MT straight drive starter to modern light PG260 starter ( as found on later GM trucks also 5.0L & 5.7L V8 iron head97-2002 trucks).Ok, so this is my issue. It is on my 1979 Corvette, not my truck, but my Vette, has its OE 4 bolt main, 350 in it. The LT headers are very close to the starter. It has a metal heat shield, but it is almost touching the header. The starter definitely has heat soak issues. So, here is my question. Anybody running a starter from a 2000ish, 4.3L on there GMT 400. The 2000 plus starter, is a smaller starter. If you are using this starter, please reply, and let me know how you like it. Yes, I know, there are a ton of mini starter options out there, and at a lot of different prices. That's not what I'm asking. I specifically what to know about the 2000 + 4.3 smaller starter. Thanks in advance.

Do Pay CLOSE ATTENTION to Starter Bolts! They're NOT the same as your old bolts and IT MATTERS HEAPS!

If your C3 motor has smaller 153T flywheel/flexplate, you'll need a "Straight" starter.

If it has 168T, ya need a "staggered" starter.

Your '79 should have HEI dist; should Not need an "R" terminal on solenoid.

*I've had only good experience w/starters & alternators from DB Electric of Kingsport TN

DB Electrical - Aftermarket Auto Parts - Starters and Alternators

DB Electrical keeps your vehicle running with premium aftermarket auto parts, including replacement alternators, starters and more.

*** '79 C3 most likely has OE 168T flywheel/flexplate --- therefore a staggered starter also.

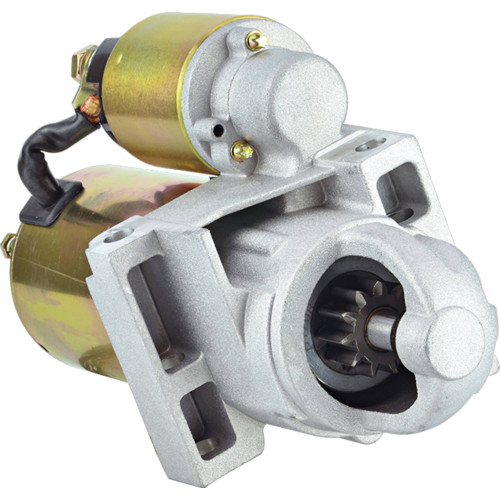

**** the modern OE PMGR starters have such a smaller profile than old OE 10MT starters, chances are it'll stand off from exhaust far enough that you should Not bother w/ blanket or shield.

Last edited: