Hipster

I'm Awesome

Mexican vortecs won't flow those numbers. I kinda look at like this. If the port stalls or goes turbulent at .500. What's happening from .500 lift to .560 not only on the upside but also down. After you killed velocity/cylinder fill on the way up then it has to try to recover and get past the wonky pressure pulse in the intake tract on the way down. On a dyno sheet if bad enough it almost looks like valve float. Everything goes erratic. Many times I've taken .580-.600 lift cams out of stuff, put similar duration back in with less lift and made more power everywhere and it runs better and is easier to tune,Like on an L31 Vortec head?

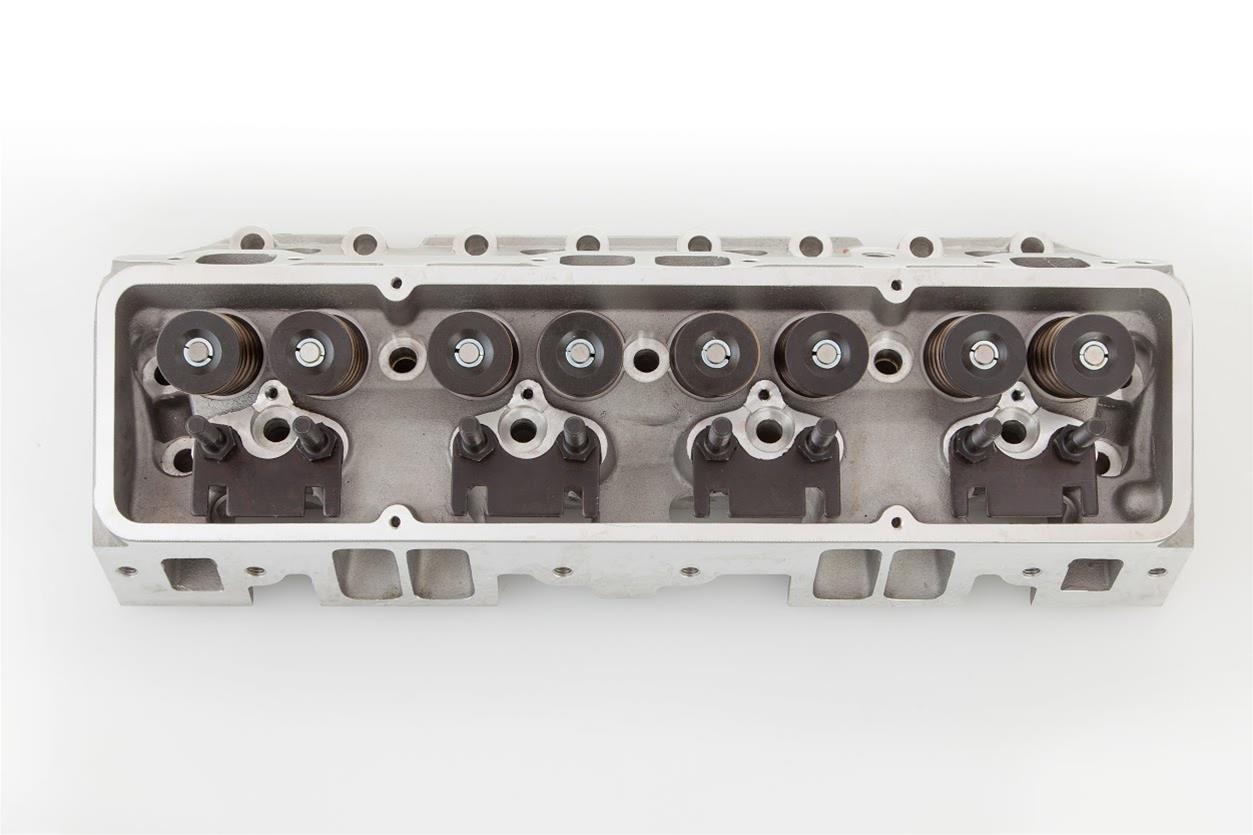

You must be registered for see images attach

Last edited: