L31MaxExpress

I'm Awesome

Get a set of DNA or Assault racing castings off Amazon or Ebay and put decent parts in them. I bought a Competition Products head improvement kit for mine for valves, springs, etc and Comp spring seats and ARP rocker arm studs. I have built 2 pair of them this way and they work great. For the $ they are a really nice set of heads. A little sanding roll cleanup and a performance valve job on them and they outflow GM Fastburns for half the money. I had Lloyd Elliot port the pair now on my 383 and they outflow the AFR 195 vortecs by a substantial margin.So, I just wanted to post an update on this. My aluminum heads keep getting pushed back by the manufacture. First it was August, now September. Next thing I know, it'll be next year.

Surely there's another option? Something that's already in stock?

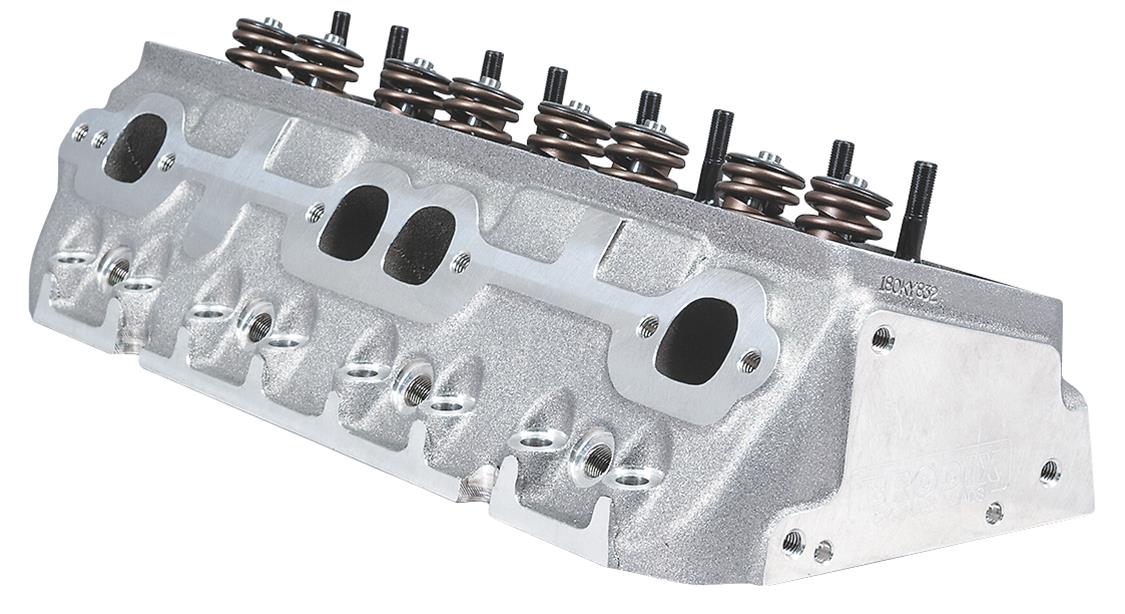

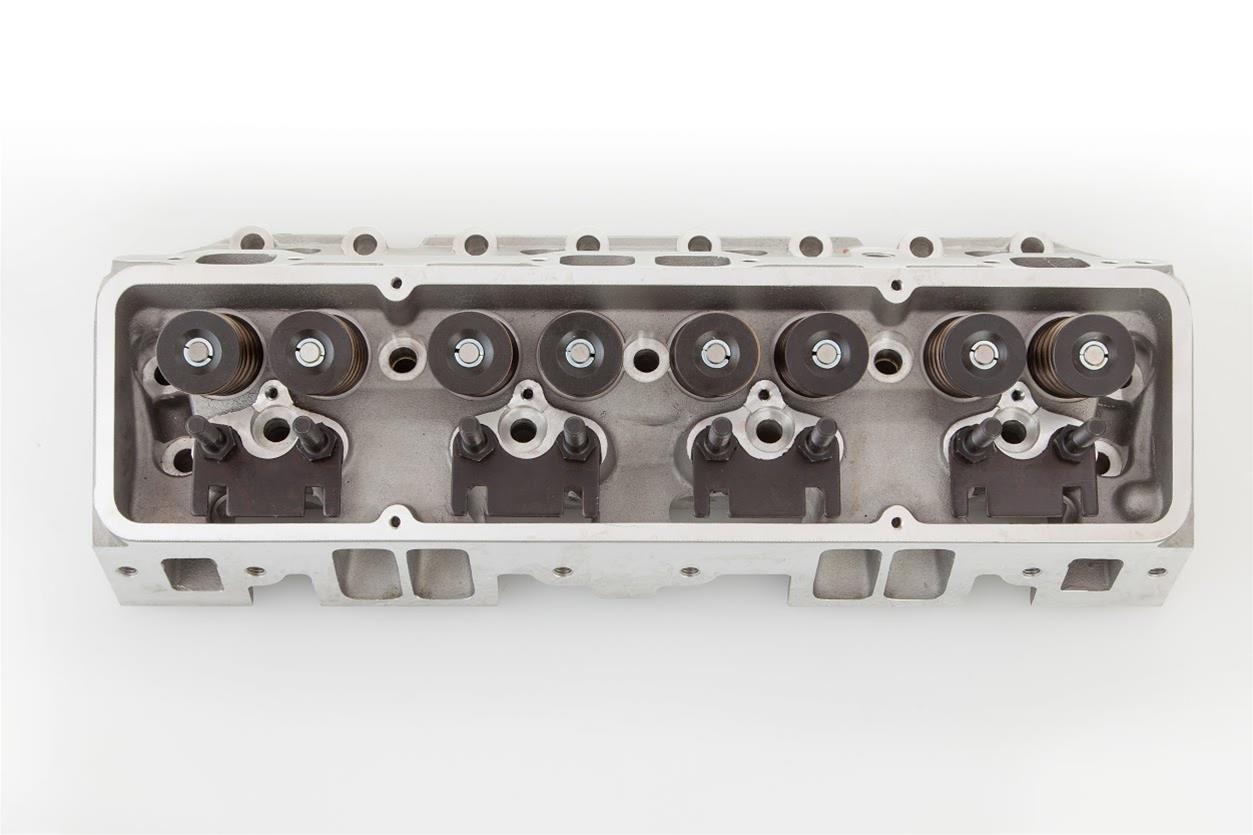

I see these, but comparing the specs with the Trick Flow heads, they are inferior. They are also roller cam heads. I'm NOT tearing that new cam out.

Flotek 101-505 FLOTEK 180cc Small Block Chevy Cylinder Heads | Summit Racing

Free Shipping - FLOTEK 180cc Small Block Chevy Cylinder Heads with qualifying orders of $109. Shop Cylinder Heads at Summit Racing.www.summitracing.com

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach