You can try downloading the electrical manual for the 1993 here. I don't see one for the 1994 but "should" be similar.How would I go about testing the control unit? I have a multimeter to test the connections, just no idea what to look for on it

88-98 Service Manuals

Over the years I have collected a bunch of GM service literature. Links to PDF Scans of service and STG manuals and a links to the Parts manuals. You'll need the FREE Adobe Acrobat reader to open these files. Get it directly from Adobe here {http://get.adobe.com/reader/} If you're not...

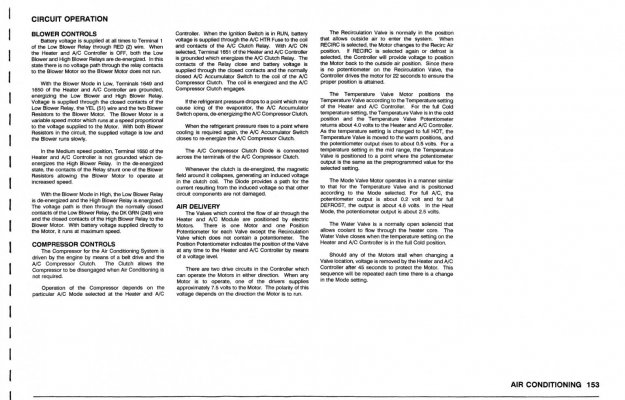

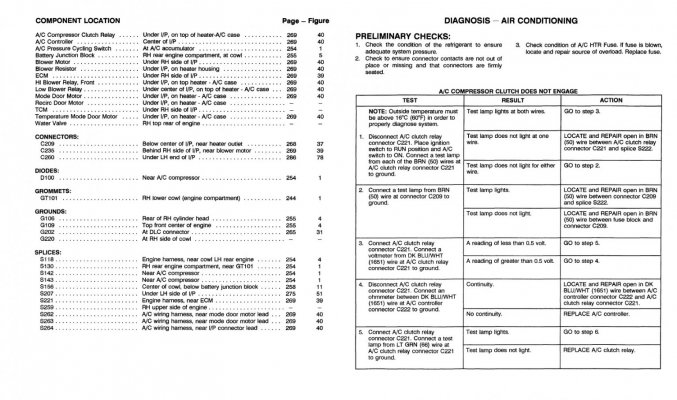

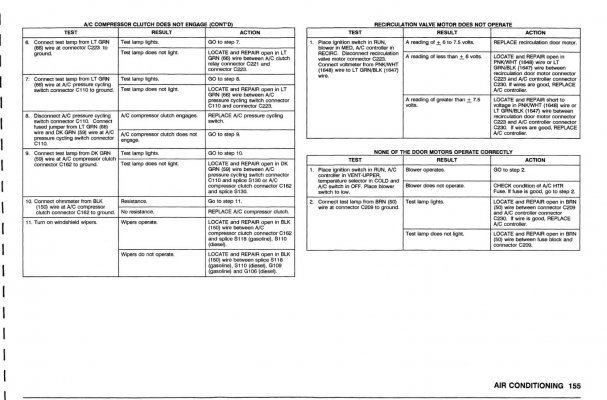

looks like page 153 on should give you the theory of operation and there are some tests later on. There is a schematic as well to help see what you're looking for.

Just be aware that, for some odd reason, there is some variation in the circuits among the years and the schematics may not reflect exactly what you have. But you should have enough info to troubleshoot. Post questions obviously if you get stuck.

here are a few screenshots ...