I have not mentioned it for a while cuz i just had better things to work on and am tired of it anyway but just in chase ANYONE has a suggestion im listening.

Yup the misfire and rough idle.

Greetings Spareparts,

Reading through your saga, I *feel* your pain. And it sounds like your

belief system is similar to mine: "If there's spark, fuel, & compression, is *has* to fire."

Whether it's a small 3.5 hp Tecumseh on an old lawnmower or the 454 under your hood,

an engine not adhering to this maxim would irritate me no end -- double if I was the one

who put it together. (!)

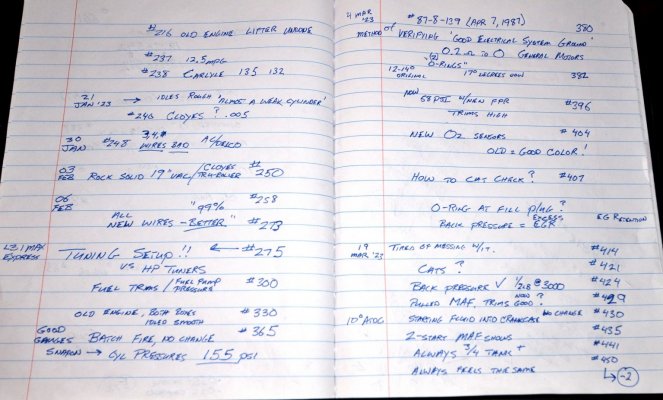

In honor of your tenacity (plus I own a new {to me} truck with an L29 in it) I decided to

read through this thread & look for a recognizable pattern. Armed with my notes, I have

3 areas of interest where you haven't already eliminated all of the variables. (1 is low

probability, 1 is possible but not probable, and 1 is probable given your recent troubleshooting

observation in #804 above.)

Q: Then why bring up all 3? A: Because there may be an interaction between

these 3 different areas, further muddying up the troubleshooting waters.

****

OK, let's start with the most probable area first. And while you read the following, please

keep this in mind: If we had coil on plug, or even coil near plug on the L29, then we wouldn't have

to worry about the firing order. (!)

But since we have 1 distributor feeding 8 cylinders, we have a couple of places in the firing order

where the sequencing stresses the spark distribution system more than others. Here are the

2 instances: 1-

8-4-3-6-

5-7-2. (NOTE: For the purposes of this discussion, I am going to posit

that when a cylinder is fired via it's spark plug wire, and the following cylinder is on the

opposite

bank, then due to physical wire routing there's little or no interaction {aka inductive coupling/"crossfire"}

that occurs.)

Given this, the following 6 sequences in the firing order (1>8, 4>3, 3>6, 6>5, 7>2, and 2>1)

are low/no interaction at the

spark plug wire level, and we can safely disregard them in a

crossfire troubleshooting discussion.

On the other hand, depending upon how the spark plug wires have been loomed together,

when cylinder 8 is fired, if the #4 wire is loomed tight to the #8 (allowing inductive coupling to occur)

then the #4 plug may spark a little in time with #8 (90° early) and then get it's regular spark

when the distributor rotor lines up and it is it's regular turn to fire.)

Guess what? Nearly nobody worries about the 8-4 issue, because the normal way we run our wires

(combined with the fact that #8 is so close to the distributor) the #8 & #4 spark plug wires don't run

alongside each other for a long enough distance that inductive coupling rears it's ugly head.

But what about the spark plug wires for #5 and #7? In the old days with the old distributor caps,

these wires ran alongside each other

all the way from the distributor cap to the adjacent spark plugs!

Depending upon how the spark plug wires were constructed (straight wire, carbon/graphite core, or

wire-wound) and how close the wires ran alongside each other, the situation can occur where the #7 plug

is stimulated to fire in time with the preceding #5 cylinder, 90° too early! (Depending upon timing

advance, it could actually be anywhere from ~100°-125° BTDC.) And then, #7 spark plug will

fire shortly afterwords at full strength at the normal ~10°-35° BTDC.

Again, if the L29 had coil on plug/coil near plug spark distribution architecture, we would not care

about the firing order at all. And some look at spark plug wires strictly in the DC (direct current)

domain. (ie: Ohmmeter measures open vs. a specified DC resistance for troubleshooting purposes.)

But in reality, we drive each spark plug wire with pulsating high KV DC, which means that we now

have to use AC theory, and include the expanding/contracting magnetic field theory when

thinking about all this.

Q: Do I think that you are suffering from inductive coupling from the 5-7 spark plug wires?

A: Possibly. IF it was happening, this would certainly explain the 'too many sparks' (more

correctly, too many flashes) as seen on your inductive timing light? (It *is* a clamp on unit?

I haven't seen the old school in-circuit timing lights since forever ago.)

To be perfectly honest, I am also thinking about those unknown valve springs, but as a

troubleshooter I decided that we need to explain why you are seeing too many timing light

flashes before we go down that path. And, more to the point, it will be relatively easy for you

to prove/disprove this wire theory. All you have to do is temporarily physically separate the

#5 & #7 wires, and then recheck the timing light. IF #7 now looks like all the others, GREAT!

If no change due to the re-routing of the #7 wire, then

don't load up the parts cannon with

yet another spark plug wire swap & continue to follow this symptom wherever it leads you.

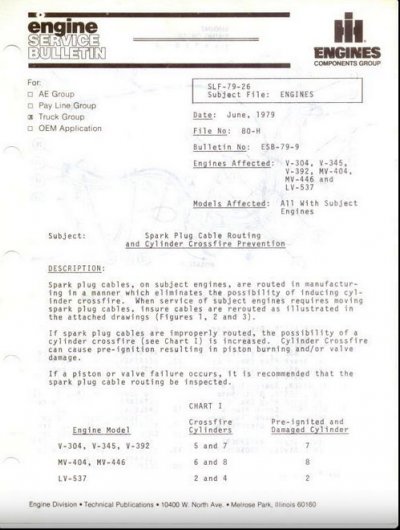

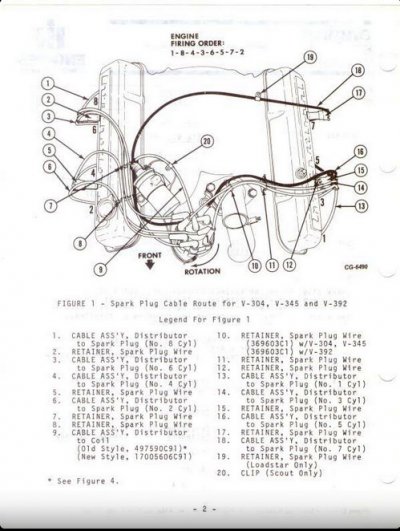

Check this out -- while researching all this, I discovered that the old International Harvester

V8 engines have the same firing order, and back in '79 they put out guidance to their dealership

mechanics in the field to be sure to route the #7 wire well away from the #5 wire (like it was done at

the factory) in order to avoid engine damage. And if they were repairing a burnt

valve or damaged piston after the fact then make sure & verify that the spark plug

wiring is done as shown on page 2. (Please see attached.)

NOTE: IH V8s have the same cylinder numbering method & firing order, but differ in

the fact that the distributor is in the front, so that is what makes the diagram look

a bit funky as compared to what we normally stare at.

FWIW, I've read about race engine failure analysis where they were trying to figure out

what went wrong in the #7 hole in the heat of battle. Some would argue that firing the

#7 spark plug that far ahead of TDC shouldn't make a difference, but we all know that

between BDC and 90° BTDC the piston rapidly accelerates from 0 to max speed during

that time, we're on the compression stroke with a combustible charge, and if all the

variables line up exactly wrong, that spark will initiate a burn way too soon. (Think

negative torque, for the charge being lit too soon will tend to (try to) push the piston

backwards down the hole.) And that negative torque (even at the tiny idle charge level)

would feel like a miss to the driver. (!)

And to prove that this isn't just an off-road/race track issue, I've attached 2 photos. The

1st is the classic Chevy distributor cap, where the wires are connected in proper firing

order, sequentially, in a clockwise circle and serviced in a timely fashion by the spinning

rotor that's mounted on top of a shaft geared directly to the camshaft.

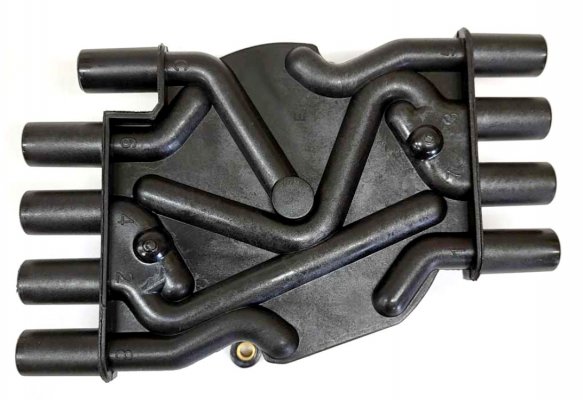

And the 2nd photo is the redesigned Chevy Vortec distributor cap, where the engineers

made sure that the #5 & #7 electrical paths at their closest are facing each other at a 90°

angle, which is how we minimize inductive coupling in wiring carrying AC (or pulsating DC)

high voltages. EDIT: The Vortec cap redesign also physically separates where the #5 & #7 wires

connect to the cap with the #3 wire in-between, which, IF you maintain that much distance

through the loom, will all but eliminate this crossfire concern for the engine builder/owner. (!)

(Note: For those readers who don't play with distributors on a daily basis,

when looking down on them (bird's eye view) the rotor spins in a clockwise direction.

Knowing this, you should be able to see the 1-8-4-3-6-5-7-2 firing order in the Vortec cap.)

****

Give this some thought, experiment with moving that #7 wire away from the #5 wire, and

see if you can't get your timing light to look the same on all 8 cylinders. Either this will

lead to a fix, OR it will be one more thing that we can add to the proven-good pile during

the Process of Elimination.

Happy hunting!

From watching the timing light flashing there is definitely extra sparking going on compared to other cylinders that are not misfiring.

Im sure i have a ignition problem but every single part is new and not fixed a thing.