Yeah time will tell on that, people online other places do say they're practically the same thing though.The 16197427 runs an $0D config same as yours, but I'm not certain that it's interchangeable with the earlier 1619xxxx in yours.

I'm not saying it's not, I'm just saying "I don't know, it certainly might".

Time will tell. See what the shop tells you.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bad running after manual swap

- Thread starter JPVortex

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

The scan tool he's using is an advanced Snap On one, with the proper GM ALDL connector adapter.Possible. Could be a wiring issue, either broken/pinched wires, or someone installed a wire into the wrong socket of a connector body.

My first guess is that there's a problem with the scan tool. What tool is this? Maybe it's got the wrong software for your application, or someone isn't connecting it properly--typing in the wrong VIN number digits, or something.

Mines a gasser sadly, thank you though!gas or diesel ? I will have a diesel /manual trans ecu in a week or so out of a 94

RacerM95

I'm Awesome

Most Welcome Sir ! I tried

So another update, shop is still having a hard time.

They’re trying to get my ECM connected to a scan tool, and the ECM seems to not want to communicate with their tool. Odd right?

The ALDL port did work I was always able to use a paper clip to get codes.

Think the ECM is going bad?

Hello JPVortex,

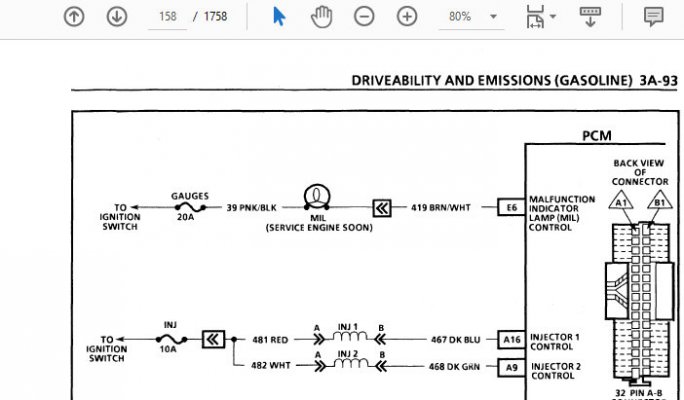

I checked the '94 FSM wiring diagrams for the TBI setup, and there are actually *3* physically separate communication paths between the '94 PCU (ECU)

and the troubleshooter in the interior. 1 for the SES light, and *2* in the ALDL connector.

* The first is a dedicated circuit (#419) so that the computer can illuminate the SES light for the human. (This works, so not our current focus, see attachment #1)

* The second is a circuit, that when grounded during KOEO tells the computer to flash numeric codes to the 'I gots no scan tool ' human in order to

communicate the failing test #, otherwise default to constant flashing 12s. Most of us know this circuit by the time honored paper clipping of pin A

(ground circuit #450) to pin B (circuit #451), which eventually leads us back to the PCM's "Diagnostic Test" pin A14.

* Guess what? When the 'I gots no scan tool' human decides to call in reinforcements, the mechanic with the scan tool/magic brick is going to connect to

the same special 12-pin OBD1 connector, and *this* is where the 3rd communication path finally gets involved. That's right, for those of you who

cheated and looked ahead at p. 3A-79 below (p. 144 in the .pdf file) ...pin M is connected via circuit #1061 to pin F9 on the PCU. If I'm not mistaken

(and I'm on thin ice) inside the computer there's gonna be a UART (Universal Asynchronous Receiver Transmitter) that's going to handshake with the

mechanic's brick, and then via "Serial Data" the 2 electronic entities will establish communication between each other, and now the scan tool can be used

to dig a lot deeper into what's up.

You must be registered for see images attach

Given this physical wiring layout, it's quite possible to have no steady SES light ever, or a steady SES light

but no flashing codes available...but the mechanic's brick works just fine?

And getting that light to work may involve tracing the power from the ignition switch to the 'GAUGES'

fuse, through the light itself, and finally the ability for the PCM pin E6 to supply a ground in order to

cause current flow through the SES lamp. So that will get you the illuminated SES warning light.

But IF you can get the 'steady on' SES light, but can't retrieve the flashing codes, then now we're all about

verifying the wiring to pin B at the ALDL connector.

But if we are getting full SES light functionality, both warning, error codes, and Field Service functions,

but we *can't* get the scan tool to connect, then at this point all I care about is the integrity of the connection

between pin M on the ALDL connector and pin F9 on the PCM. (ECU)

****

By the way, I share all of the above from fixing 'no worky' yet known-good avionics test equipment that

kept us from working on the actual writeup. I'm sincerely hoping to come back to this thread and read

that you've found the break in the serial data communication path and that the scan tool is doing the

chitter chatter with your PCM. (Assuming that the treasure yard PCM acts the same way, making the

probability that the PCM is the victim of a bad wire and not the actual perpetrator of the whole

incommunicado thing.)

And if the replacement PCM fixes everything, it was still good practice for yours truly to wade around in the OBD1 TBI

wiring diagrams that document the ALDL<>PCM area. :0)

Give everything between the ALDL connector and your PCM some careful scrutiny & let us know what you find.

Best of luck with the hunt. We gotta get your GMT400 back on the road, especially since you had the good taste

to upgrade the manual tranny in it. :0)

Cheers --

Attachments

Last edited:

Wow! Thank you so much for this write up, it is extremely appreciated. Can pretty much rule everything out but the connection between pin M and F9 on the PCM. Seeing as the SES light functions completely normal and also the paperclip in pins A & B do show the codes. I'm hoping that throwing this cheap PCM in will do the trick, but I will find out tomorrowHello JPVortex,

I checked the '94 FSM wiring diagrams for the TBI setup, and there are actually *3* physically separate communication paths between the '94 PCU (ECU)

and the troubleshooter in the interior. 1 for the SES light, and *2* in the ALDL connector.

* The first is a dedicated circuit (#419) so that the computer can illuminate the SES light for the human. (This works, so not our current focus, see attachment #1)

* The second is a circuit, that when grounded during KOEO tells the computer to flash numeric codes to the 'I gots no scan tool ' human in order to

communicate the failing test #, otherwise default to constant flashing 12s. Most of us know this circuit by the time honored paper clipping of pin A

(ground circuit #450) to pin B (circuit #451), which eventually leads us back to the PCM's "Diagnostic Test" pin A14.

* Guess what? When the 'I gots no scan tool' human decides to call in reinforcements, the mechanic with the scan tool/magic brick is going to connect to

the same special 12-pin OBD1 connector, and *this* is where the 3rd communication path finally gets involved. That's right, for those of you who

cheated and looked ahead at p. 3A-79 below (p. 144 in the .pdf file) ...pin M is connected via circuit #1061 to pin F9 on the PCU. If I'm not mistaken

(and I'm on thin ice) inside the computer there's gonna be a UART (Universal Asynchronous Receiver Transmitter) that's going to handshake with the

mechanic's brick, and then via "Serial Data" the 2 electronic entities will establish communication between each other, and now the scan tool can be used

to dig a lot deeper into what's up.

You must be registered for see images attach

Given this physical wiring layout, it's quite possible to have no steady SES light ever, or a steady SES light

but no flashing codes available...but the mechanic's brick works just fine?

And getting that light to work may involve tracing the power from the ignition switch to the 'GAUGES'

fuse, through the light itself, and finally the ability for the PCM pin E6 to supply a ground in order to

cause current flow through the SES lamp. So that will get you the illuminated SES warning light.

But IF you can get the steady on SES light, but can't retrieve the codes, then now we're all about

verifying the wiring to pin B at the ALDL connector.

But if we are getting full SES light functionality, both warning, error codes, and Field Service functions,

but we *can't* get the scan tool to connect, then at this point all I care about is the integrity of the connection

between pin M on the ALDL connector and pin F9 on the PCM. (ECU)

****

By the way, I share all of the above from fixing 'no worky' yet known-good avionics test equipment that

kept us from working on the actual writeup. I'm sincerely hoping to come back to this thread and read

that you've found the break in the serial data communication path and that the scan tool is doing the

chitter chatter with your PCM. (Assuming that the treasure yard PCM acts the same way, making the

probability that the PCM is the victim of a bad wire and not the actual perpetrator of the whole

incommunicado thing.)

And if the replacement PCM fixes everything, it was still good practice for yours truly to wade around in the OBD1 TBI

wiring diagrams that document the ALDL<>PCM area.

:0)

Give everything between the ALDL connector and your PCM some careful scrutiny & let us know what you find.

Best of luck with the hunt. We gotta get your GMT400 back on the road, especially since you had the good taste

to upgrade the manual tranny in it. :0)

Cheers --

I really do need to get this thing back on the road! I swapped it, drove it for a week before I had an accident at work and slipped a lower disc in my back, so I couldn't drive it. And when it finally did settle down enough this is the issues I run into lol.

I'm hoping between a different PCM and replacing grounds that are missing, and diagnosing power to the coil(direct wiring to battery to test) that something will give and the issue will be found!

So real quick question. Is there any decent alternative location to put the ground from the firewall under the heater hoses to the cylinder head? Particularly the cylinder head side.

It’s a total pain to reach back there to get a ground strap in, any other more reasonable place that’s somewhat close to the factory spot?

It’s a total pain to reach back there to get a ground strap in, any other more reasonable place that’s somewhat close to the factory spot?

Is access any better / easier if you come up from underneath, instead of from under the hood? I suppose the starter and exhaust pipes interfere.

At least there’s no ATF dipstick in your way anymore on the passenger’s side head.

On many GM vehicles I’ve seen, the ground strap is attached to the head which supports the alternator. I won’t say that is a hard rule, but it seems common and arguably justified.

Thus, on my 1998 the alternator is on the passenger’s side (as is the ground strap, head-to-firewall).

Where is the alternator on yours?

At least there’s no ATF dipstick in your way anymore on the passenger’s side head.

On many GM vehicles I’ve seen, the ground strap is attached to the head which supports the alternator. I won’t say that is a hard rule, but it seems common and arguably justified.

Thus, on my 1998 the alternator is on the passenger’s side (as is the ground strap, head-to-firewall).

Where is the alternator on yours?

Last edited:

I might have better luck going from below, haven’t really thought of that lol.Is access any better / easier if you come up from underneath, instead of from under the hood? I suppose the starter and exhaust pipes interfere.

At least there’s no ATF dipstick in your way anymore on the passenger’s side head.

On many GM vehicles I’ve seen, the ground strap is attached to the head which supports the alternator. I won’t say that is a hard rule, but it seems common and arguably justified.

Thus, on my 1998 the alternator is on the passenger’s side (as is the ground strap, head-to-firewall).

Where is the alternator on yours?

If I can’t get the strap onto the back of the passenger cylinder head would the farthest back intake manifold bolt stud work aswell? Or would that be a no go?

On my 94 TBI the alternator is actually on the drivers side.

Boy… I got a lot of wiring to redo,

- adding these grounds

- direct wiring the coil to the battery for testing

- temporarily cutting the tach output wire for testing then reconnecting it

- possibly new coil connector

- there’s a pcm ground I want to redo coming off the harness to intake. I think stock 2 PCM grounds were used, but one of the 2 grounds had 2 wires in the terminal. Mine was redone at one point and they didn’t use 2 wires in 1 terminal, so I have 3 PCM grounds now. The “aftermarket” one looks a bit janky.

- adding these grounds

- direct wiring the coil to the battery for testing

- temporarily cutting the tach output wire for testing then reconnecting it

- possibly new coil connector

- there’s a pcm ground I want to redo coming off the harness to intake. I think stock 2 PCM grounds were used, but one of the 2 grounds had 2 wires in the terminal. Mine was redone at one point and they didn’t use 2 wires in 1 terminal, so I have 3 PCM grounds now. The “aftermarket” one looks a bit janky.

Similar threads

- Replies

- 14

- Views

- 2K

- Replies

- 0

- Views

- 190

- Replies

- 9

- Views

- 2K

- Replies

- 6

- Views

- 331

- Replies

- 267

- Views

- 14K

Members online

- Drunkcanuk

- TheDogsSuburban94

- JPVortex

- 99tahoez71

- Dcsmith1922

- Jimmy D

- TXStepside

- 62barsoom

- tcmechanic2

- Blake88

- jus10inbrla

- silver94

- IndexOf0

- Herbk

- Bob2650

- yevgenievich

- Stumppuller

- docstoy

- Dachechinwolf

- Nad_Yvalhosert

- Boots97

- Mangonesailor

- chriscc07

- JS45

- Komet

- grampadirt

- mdp96

- obs_dude-tx

- Javielbond

- Charlesteneows

- Jlojub

- Kmoody528

- DavidH88

- Oilisgod

- evilunclegrimace

- Scooterwrench

- MarKist

- DaddyD

- 93olegrey

- mehcs

- Wh4t3v3rs

- Crawlblind

- solaralexx

- 98k250074

- Zack8

- Orpedcrow

- Miahjoe

- Brickyard

- zachjacobs223

- Spareparts

Total: 1,853 (members: 66, guests: 1,787)