It's supposed to have a .500 boost valve. The issue is, it's been doing this since I bought the thing. Is there an adjustment, spring, or something that is holding back the shift until a higher speed or more torque? Like I said, I have no idea...Sonnax .500 boost valve and TV plunger and sleeve kit will help if not already installed

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

700R4 Information Thread

- Thread starter NickTransmissions

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

It's supposed to have - but does it have a .500 boost valve? That is the question...It's supposed to have a .500 boost valve...

Along with the questions about valve body parts I mentioned..I'd also expect to see other VB mods such as, but not limited to:

- Line bias valve blocked off

- TV limit valve shimmed

- TV boost valve updated (Transgo or Sonnax)

- TV plunger and sleeve (Sonnax)

- 3-2 downshift valve blocked inboard

- 1-2 accumulator regulator valve fitted with a different spring for less accumulator flow to the acc side of the 1-2 acc piston in the housing

- Governor modified to match intended performance (did you check the governor?)

- possibly one or more check balls deleted from VB or case based on other mods performed

This stuff needs to be verified...ESPECIALLY given that's it has been behaving as described since you bought it.

You may be looking for some, simple easy fix to resolve but I'd caution you to not get married to that notion, if that is the case...Based on everything you've relayed, trans has to be investigated, at minimum, to confirm hydraulics have been so-modified/updated to meet your performance requirements as well as address common issues w/these transmissions. I'd also want to know what the pump clearance was but unless you're willing to pull it apart, wash everything up then measure pump clearance, there's no way we can assess the condition of the pump internally, which could be the main (or one of) driver of your symptoms.

ETA - check your TV bracket-cable geometry as this can also cause your problems. The geometry has to be spot-on, not just 'close'...Otherwise, line pressure rise will be suboptimal..It's probably the closest thing to a quick/easy fix that I can give to you...

Check all the above, let me know what you find and we can go from there.

Last edited:

Thanks Nick for your replies. Since I'm in Tonopah AZ (not NV ha ha), would you be able to do this if I just send the valve body to you instead of the complete trans?Based on everything you've relayed, trans has to be investigated, at minimum, to confirm hydraulics have been so-modified/updated to meet your performance requirements as well as address common issues w/these transmissions.

The TV cable and brackets are OE on my Throttle Body. I would hope they're correct. When I installed this trans I floored the pedal and it pops the adjustment back to this position. Do I need higher pressures at WOT throughout the gears? Maybe I can install that spring loaded TV cable equalizer (what ever it's called) to add some pull on it?check your TV bracket-cable geometry as this can also cause your problems. The geometry has to be spot-on, not just 'close'...Otherwise, line pressure rise will be suboptimal..It's probably the closest thing to a quick/easy fix that I can give to you...

If the bracket itself is factory then it should be correct (shame - was hoping that would be your problem, or at least give you some hope of a relatively straight-forward, low level-of-effort solution).Thanks Nick for your replies. Since I'm in Tonopah AZ (not NV ha ha), would you be able to do this if I just send the valve body to you instead of the complete trans?

The TV cable and brackets are OE on my Throttle Body. I would hope they're correct. When I installed this trans I floored the pedal and it pops the adjustment back to this position. Do I need higher pressures at WOT throughout the gears? Maybe I can install that spring loaded TV cable equalizer (what ever it's called) to add some pull on it?

Send me a PM with your name and good contact number and I'll give you a call tomorrow (or whenever is most convenient for you) and we can go from there. Tonopah is appx 6 hours from me (I used to live in North Phoenix back in the early 2000s so am familiar with the area).

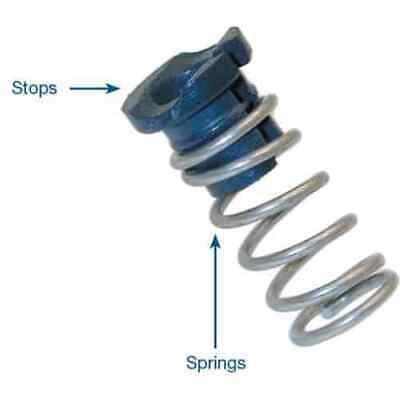

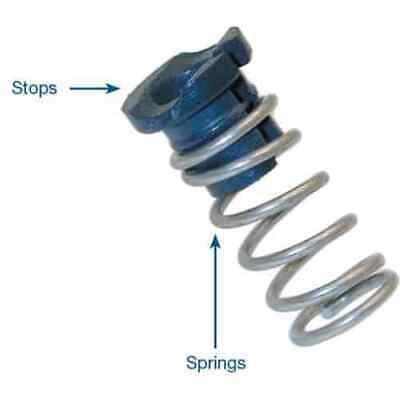

I found what I was looking for - something like this?Maybe I can install that spring loaded TV cable equalizer (what ever it's called) to add some pull on it?

Sonnax AS1-01K TV Cable Corrector Kit GM 200-4R 200C 700R4/4L60 Ford AOD AXOD | eBay

TV Cable Corrector KitGM 200-4R, 200C, 700R4/4L60, Ford AOD, AXOD Springs (5)Stops (5)For Holley CarburetorsIn most GM and Ford transmissions with cables, the throttle valve cable pulls out of adjustment at wide-open throttle. This is typically caused by inaccurate geometry of the throttle shaft...

www.ebay.com

You can try it but if you have the factory bracket and induction, your geometry should be correct (should be). It specifically mentions that it's a fix for applications with otherwise incorrect geometry. If that doesn't work, trans has to be investigated.I found what I was looking for - something like this?

Sonnax AS1-01K TV Cable Corrector Kit GM 200-4R 200C 700R4/4L60 Ford AOD AXOD | eBay

TV Cable Corrector KitGM 200-4R, 200C, 700R4/4L60, Ford AOD, AXOD Springs (5)Stops (5)For Holley CarburetorsIn most GM and Ford transmissions with cables, the throttle valve cable pulls out of adjustment at wide-open throttle. This is typically caused by inaccurate geometry of the throttle shaft...www.ebay.com

At minimum, the TV cable should be adjusted such that it's applying a little bit of preload on the TV plunger in the valve body. With preload, as soon as you tap the gas, TV boost pressure should spike up and stay ahead of torque-driven line pressure demand.

Sean Buick 76

I'm Awesome

I will dig up the article by Art Carr where he talks about the fact that the 700R4 isn’t designed from factory to shift from 3rd to 4th under full throttle.

I run a billet 200R4 at about 800 Hp and it shifts into 4th at full throttle each time without issue. 4.56 gear, dead hooking to 135 mph in the quarter.

- GM designed the 700-R4 valve body to prevent overdrive access at full throttle to ensure survival. Not a good sign. The 200-4R is free of such nonsense and is ready for big-block overdrive blasting with only minor beefing.

I run a billet 200R4 at about 800 Hp and it shifts into 4th at full throttle each time without issue. 4.56 gear, dead hooking to 135 mph in the quarter.

Correct about the 700R4, though you can modify it to do so, if that is desired.I will dig up the article by Art Carr where he talks about the fact that the 700R4 isn’t designed from factory to shift from 3rd to 4th under full throttle.

- GM designed the 700-R4 valve body to prevent overdrive access at full throttle to ensure survival. Not a good sign. The 200-4R is free of such nonsense and is ready for big-block overdrive blasting with only minor beefing.

I run a billet 200R4 at about 800 Hp and it shifts into 4th at full throttle each time without issue. 4.56 gear, dead hooking to 135 mph in the quarter.

@PlayingWithTBI is having a no 2-3 upshift condition at WOT, which should be happening, all other things equal and working correctly...

1. OUTSTANDING thread, NickTransmissions.

2. I would add a photo of a '700 new enough to have the trans case molding seam--the crescent-shaped "upside-down U" casting mark that goes through the upper trans cooler fitting. Cases new enough to have that seam are also new enough to have most of the year-to-year "upgrades" for the troubles that plagued the early models. This crescent seam can be seen in the opening picture of your "700R4 Teardown and Inspection" video, but a better photo would be nice.

3. Similarly, a nice picture of the auxiliary valve body might be helpful. Again, I don't care specifically about the Aux. valve body per se, but any trans new enough to have the Aux. valve body is also new enough to have the most-needed internal upgrades. It's be nice for newbies to understand what the Aux. valve body is, and what it does.

2. I would add a photo of a '700 new enough to have the trans case molding seam--the crescent-shaped "upside-down U" casting mark that goes through the upper trans cooler fitting. Cases new enough to have that seam are also new enough to have most of the year-to-year "upgrades" for the troubles that plagued the early models. This crescent seam can be seen in the opening picture of your "700R4 Teardown and Inspection" video, but a better photo would be nice.

3. Similarly, a nice picture of the auxiliary valve body might be helpful. Again, I don't care specifically about the Aux. valve body per se, but any trans new enough to have the Aux. valve body is also new enough to have the most-needed internal upgrades. It's be nice for newbies to understand what the Aux. valve body is, and what it does.

Thanks, @Schurkey -Here's some 'vintage' info with visual differentiators between them:1. OUTSTANDING thread, NickTransmissions.

2. I would add a photo of a '700 new enough to have the trans case molding seam--the crescent-shaped "upside-down U" casting mark that goes through the upper trans cooler fitting. Cases new enough to have that seam are also new enough to have most of the year-to-year "upgrades" for the troubles that plagued the early models. This crescent seam can be seen in the opening picture of your "700R4 Teardown and Inspection" video, but a better photo would be nice.

3. Similarly, a nice picture of the auxiliary valve body might be helpful. Again, I don't care specifically about the Aux. valve body per se, but any trans new enough to have the Aux. valve body is also new enough to have the most-needed internal upgrades. It's be nice for newbies to understand what the Aux. valve body is, and what it does.

| Vintage | Key Characteristics | Visual Indicator(s) |

| 1982-E1984 | 27-spline, narrow input shaft and first design input drum and pump (Never use these in any performance-oriented application) | Input shaft has 27 splines |

| L1984-1986 | 30-spline input shaft, 2nd design input drum and pump assembly | 30 splines on input shaft & a '4', '5' or '6' as the first integer in the alpha-numeric code stamped into the passenger side-rear of the case just above the pan rail |

| 1987 | 30-spline input shaft, 2nd design input drum, pump assembly AND 1st year for auxiliary valve body; 2nd design spacer plate | A '7' as the first integer in the alpha-numeric code stamped into the passenger side-rear of the case just above the pan rail |

| 1988-1992 | 30-spline input shaft, 3rd design input drum, 3rd design pump assembly and 2nd design valve body (eliminates mechanical TCC lock up capability in VB); 3rd design spacer plate | Large, upside down crease on passenger side of case, looping over the servo bore from the rear of the bell to appx 2/3" the way towards the rear of the case |

| 1993 | 3rd design valve body and 4th design spacer plate (3rd VB check ball added for reverse input Installed in Vettes, F-Bodies, Caprices, etc | Large, upside down crease on passenger side of case, looping over the servo bore from the rear of the bell to appx 2/3" the way towards the rear of the case AND a '3' as the first integer in the alpha-numeric code stamped into the passenger side-rear of the case just above the pan rail |

<Will add pics later today or tomorrow>

Last edited:

Similar threads

- Replies

- 60

- Views

- 15K

- Replies

- 3

- Views

- 1K