You did! Cool hopefully it will get some notice and we'll be seeing cleaner dog houses.Good thread. Made it a sticky.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Let's get connected!!!

- Thread starter Scooterwrench

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

I have no idea what you just said but it sounds good. Care to enlighten an old timer?I have slowly been adding to my collection of .20 and smaller. It comes in my wire pigtails that I use in the dealership. I end up delinking the connector and just replace the bad pins and save the rest for future use

I believe that if this gets stickied, it needs to be under "Audio & Electronics".

I throw away those old plastic covered crimp terminals when I find them now. I only buy the heat shrink connectors. If your crimp survives a tug test, they're a decent permanent fix. As a dealer tech we were issued heat-shrink butt connectors in our OEM produced recall kits.

22-18 gauge heat shrink butt connectors:

www.amazon.com/gp/product/B07L5JW5G9/

The "most proper" fix is to replace a run of wire from connector to connector with a new terminal end crimped on with the correct crimper. When I was an Air Force AGE technician, some of our equipment had to be maintained to nuclear surety standards. One of those standards is that there can only be one wiring repair in a wire. To this day I try to stick with that when I can. Once I'm confronted with the need for a second splice I start looking at how difficult it would be to run another complete wire.

Invest in proper crimpers for the terminal you're assembling. I recently had to purchase a pair of Packard 56 crimpers for use on older vehicles. Pretty much all that wiring on older vehicles (squarebody and older) was done with Packard 56 terminals. The terminals look like regular spade terminals, but they're slightly bigger and can handle more current. Modern crimpers with the "A-B-C-D-E" sizing on them aren't big enough for Packard 56 terminals.

Packard 56 crimper:

www.amazon.com/gp/product/B00O7S3148/

Packard 56 terminals:

www.amazon.com/gp/product/B00B460HHK/

If you're building a harness from scratch and can use whatever you want, I really like the cheapskate Amazon terminal kits. They're proof that Deutsch and Metri-Pack connectors are way overpriced for being bits of plastic and tin. The downside is that they're all low-current. You can't run your alternator charging wire or starter solenoid wire through them.

www.amazon.com/Waterproof-Automotive-Electrical-Connector-Connectors/dp/B09GN8TQYQ/

If you're doing electrical work, at some point you're going to need to build the heavier stuff, like battery terminals with terminal lugs. Step up and buy the right lugs and crimper. Once they're crimped, heat shrink them!

Hydraulic terminal lug crimper:

www.harborfreight.com

1 AWG 3/8" terminal lugs:

www.harborfreight.com

1 AWG 3/8" terminal lugs:

www.amazon.com/gp/product/B09QKTBHX9/

Big heat shrink:

www.amazon.com/gp/product/B07FPKVMTW/

www.amazon.com/gp/product/B07FPDBGYH/

Military-style battery terminals don't look sexy, but they're absolutely easy and reliable to work with, once you've put terminal lugs on your cables.

www.amazon.com/gp/product/B0B6H1LC4V/

Finally, secure your wiring so that it doesn't rub and chafe. Sheathe your wiring. I hate the old corrugated stuff. The newer split sleeving is good. If you want rugged, use Adel clamps for securing your wiring. If you're going to be in there a lot (i.e. racecar), use rivetable ziptie holders.

Sheathing:

www.amazon.com/gp/product/B07FXF12HC/

www.amazon.com/gp/product/B07FW3MKGH/

Adel clamps:

www.harborfreight.com

Rivetable ziptie holders:

www.harborfreight.com

Rivetable ziptie holders:

www.amazon.com/GTSE-Black-Screw-Mount-Cable/dp/B07ZKNQ949/

I throw away those old plastic covered crimp terminals when I find them now. I only buy the heat shrink connectors. If your crimp survives a tug test, they're a decent permanent fix. As a dealer tech we were issued heat-shrink butt connectors in our OEM produced recall kits.

22-18 gauge heat shrink butt connectors:

www.amazon.com/gp/product/B07L5JW5G9/

The "most proper" fix is to replace a run of wire from connector to connector with a new terminal end crimped on with the correct crimper. When I was an Air Force AGE technician, some of our equipment had to be maintained to nuclear surety standards. One of those standards is that there can only be one wiring repair in a wire. To this day I try to stick with that when I can. Once I'm confronted with the need for a second splice I start looking at how difficult it would be to run another complete wire.

Invest in proper crimpers for the terminal you're assembling. I recently had to purchase a pair of Packard 56 crimpers for use on older vehicles. Pretty much all that wiring on older vehicles (squarebody and older) was done with Packard 56 terminals. The terminals look like regular spade terminals, but they're slightly bigger and can handle more current. Modern crimpers with the "A-B-C-D-E" sizing on them aren't big enough for Packard 56 terminals.

Packard 56 crimper:

www.amazon.com/gp/product/B00O7S3148/

Packard 56 terminals:

www.amazon.com/gp/product/B00B460HHK/

If you're building a harness from scratch and can use whatever you want, I really like the cheapskate Amazon terminal kits. They're proof that Deutsch and Metri-Pack connectors are way overpriced for being bits of plastic and tin. The downside is that they're all low-current. You can't run your alternator charging wire or starter solenoid wire through them.

www.amazon.com/Waterproof-Automotive-Electrical-Connector-Connectors/dp/B09GN8TQYQ/

If you're doing electrical work, at some point you're going to need to build the heavier stuff, like battery terminals with terminal lugs. Step up and buy the right lugs and crimper. Once they're crimped, heat shrink them!

Hydraulic terminal lug crimper:

Hydraulic Wire Crimping Tool

Amazing deals on this Hydraulic Wire Crimping Tool at Harbor Freight. Quality tools & low prices.

www.amazon.com/gp/product/B09QKTBHX9/

Big heat shrink:

www.amazon.com/gp/product/B07FPKVMTW/

www.amazon.com/gp/product/B07FPDBGYH/

Military-style battery terminals don't look sexy, but they're absolutely easy and reliable to work with, once you've put terminal lugs on your cables.

www.amazon.com/gp/product/B0B6H1LC4V/

Finally, secure your wiring so that it doesn't rub and chafe. Sheathe your wiring. I hate the old corrugated stuff. The newer split sleeving is good. If you want rugged, use Adel clamps for securing your wiring. If you're going to be in there a lot (i.e. racecar), use rivetable ziptie holders.

Sheathing:

www.amazon.com/gp/product/B07FXF12HC/

www.amazon.com/gp/product/B07FW3MKGH/

Adel clamps:

Rubber Insulated Clamp Assortment, 18 Piece

Amazing deals on this 18 Piece Rubber Insulated Clamps at Harbor Freight. Quality tools & low prices.

www.amazon.com/GTSE-Black-Screw-Mount-Cable/dp/B07ZKNQ949/

Thanks for those links Erik. I like those hydraulic crimpers and can see other uses for those too like making up the brake hoses I use on these bikes I build.I believe that if this gets stickied, it needs to be under "Audio & Electronics".

I throw away those old plastic covered crimp terminals when I find them now. I only buy the heat shrink connectors. If your crimp survives a tug test, they're a decent permanent fix. As a dealer tech we were issued heat-shrink butt connectors in our OEM produced recall kits.

22-18 gauge heat shrink butt connectors:

www.amazon.com/gp/product/B07L5JW5G9/

The "most proper" fix is to replace a run of wire from connector to connector with a new terminal end crimped on with the correct crimper. When I was an Air Force AGE technician, some of our equipment had to be maintained to nuclear surety standards. One of those standards is that there can only be one wiring repair in a wire. To this day I try to stick with that when I can. Once I'm confronted with the need for a second splice I start looking at how difficult it would be to run another complete wire.

Invest in proper crimpers for the terminal you're assembling. I recently had to purchase a pair of Packard 56 crimpers for use on older vehicles. Pretty much all that wiring on older vehicles (squarebody and older) was done with Packard 56 terminals. The terminals look like regular spade terminals, but they're slightly bigger and can handle more current. Modern crimpers with the "A-B-C-D-E" sizing on them aren't big enough for Packard 56 terminals.

Packard 56 crimper:

www.amazon.com/gp/product/B00O7S3148/

Packard 56 terminals:

www.amazon.com/gp/product/B00B460HHK/

If you're building a harness from scratch and can use whatever you want, I really like the cheapskate Amazon terminal kits. They're proof that Deutsch and Metri-Pack connectors are way overpriced for being bits of plastic and tin. The downside is that they're all low-current. You can't run your alternator charging wire or starter solenoid wire through them.

www.amazon.com/Waterproof-Automotive-Electrical-Connector-Connectors/dp/B09GN8TQYQ/

If you're doing electrical work, at some point you're going to need to build the heavier stuff, like battery terminals with terminal lugs. Step up and buy the right lugs and crimper. Once they're crimped, heat shrink them!

Hydraulic terminal lug crimper:

1 AWG 3/8" terminal lugs:

Hydraulic Wire Crimping Tool

Amazing deals on this Hydraulic Wire Crimping Tool at Harbor Freight. Quality tools & low prices.www.harborfreight.com

www.amazon.com/gp/product/B09QKTBHX9/

Big heat shrink:

www.amazon.com/gp/product/B07FPKVMTW/

www.amazon.com/gp/product/B07FPDBGYH/

Military-style battery terminals don't look sexy, but they're absolutely easy and reliable to work with, once you've put terminal lugs on your cables.

www.amazon.com/gp/product/B0B6H1LC4V/

Finally, secure your wiring so that it doesn't rub and chafe. Sheathe your wiring. I hate the old corrugated stuff. The newer split sleeving is good. If you want rugged, use Adel clamps for securing your wiring. If you're going to be in there a lot (i.e. racecar), use rivetable ziptie holders.

Sheathing:

www.amazon.com/gp/product/B07FXF12HC/

www.amazon.com/gp/product/B07FW3MKGH/

Adel clamps:

Rivetable ziptie holders:

Rubber Insulated Clamp Assortment, 18 Piece

Amazing deals on this 18 Piece Rubber Insulated Clamps at Harbor Freight. Quality tools & low prices.www.harborfreight.com

www.amazon.com/GTSE-Black-Screw-Mount-Cable/dp/B07ZKNQ949/

OK man,As much as I hate contributing to Amazon's monopoly, being able to check my past orders is incredibly handy for making parts lists like this. They're also fast and efficient at delivering obscure mechanical bits and tools directly to my door in a timely manner.

Please don't pollute this thread with personal chit-chat!

I was just asked if I had completed this tutorial and with thanks to Erik and his links to some of the tools that I used(and some of his) I have.

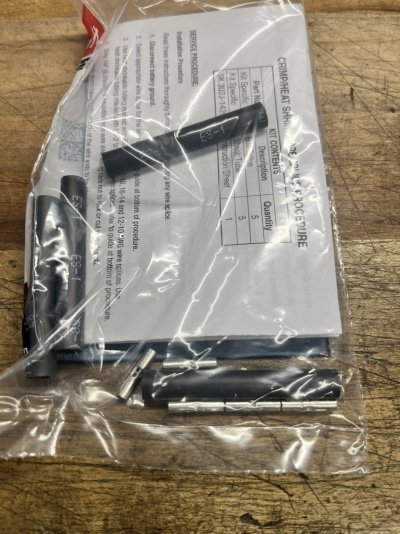

Often times we have issues with connectors. The repair procedure will have the technician replace the wire pigtail. Sometimes it’s only one wire that’s bad so instead of cutting all the wires to the connector I de-pin the connector and only replace what is bad. We get these kits for the pigtail to make the repair I collect the unused terminals and shrink tube for other usesI have no idea what you just said but it sounds good. Care to enlighten an old timer?

Attachments

That's the way to do it,better than making a splice any day. I'm surprised the factory is furnishing a whole pigtail that has to be spliced in rather than just the terminals to repair the connector. They send you to school to learn the correct way to make that repair but only send you the parts to half ass it it up.

Go figure!

Go figure!

Great article! I just wanted to add a couple of tools I have helpful.

Lisle 56500 Terminal Tool https://a.co/d/djdW8Fu

Dorman 90707 Battery Lug Crimper https://a.co/d/58uRepj

Lisle 56500 Terminal Tool https://a.co/d/djdW8Fu

Dorman 90707 Battery Lug Crimper https://a.co/d/58uRepj

Similar threads

- Replies

- 2

- Views

- 194

- Replies

- 7

- Views

- 1K

Members online

- Dyldog

- mgto70

- 99xcss4

- cdone

- ZSC-114

- Sle-z_90

- Zavalaj05

- BeXtreme

- MCLMM

- jus10inbrla

- 0xDEADBEEF

- Supercharged111

- giraffe

- mikesparker

- Caman96

- jlake97

- JPVortex

- JEFF995

- theoneandonlywhytry

- jdeere3010

- CruiseLifeB

- Jimmy D

- benpat

- Cheezebandit

- Poon_goon

- DerekTheGreat

- heskahoka

- FLGS400

- Jen42069

- Road Trip

- Nopainnogain445

- Jskingry

- Glorygarci

- GaryR

- SilverDollar

- L31MaxExpress

- k1500 97

- Bluechevy1996

- Pinger

- vince72

- Scooterwrench

- fancyTBI

- bingobobby

- Dachechinwolf

- Jwill945

- Eddy98

- ol-Betsy

- jgreen16

- 90sprobs

- RabbitsOnTheMoon

Total: 1,727 (members: 57, guests: 1,670)