Sean Buick 76

I'm Awesome

I only use V bands now that I’ve tried them. Not just any V bands these ones lock in positively and no leaks. I’m currently using 2.5, 3.5 and 5” V bands from them on turbo applications.My tip of the day for anyone considering Hedman headers. Anytime I install a Hedman header of any kind with a 3" collector, I cut the dumb ball and socket end off and use these, much less of a PITA over time. Flowmaster also makes these in 3.5" to 3" for larger header setups on bigger engines.

Flowmaster R3025 Flowmaster Reducer Cone

Forms smooth transitions from one pipe diameter size to another. Available in various sizes.www.holley.com

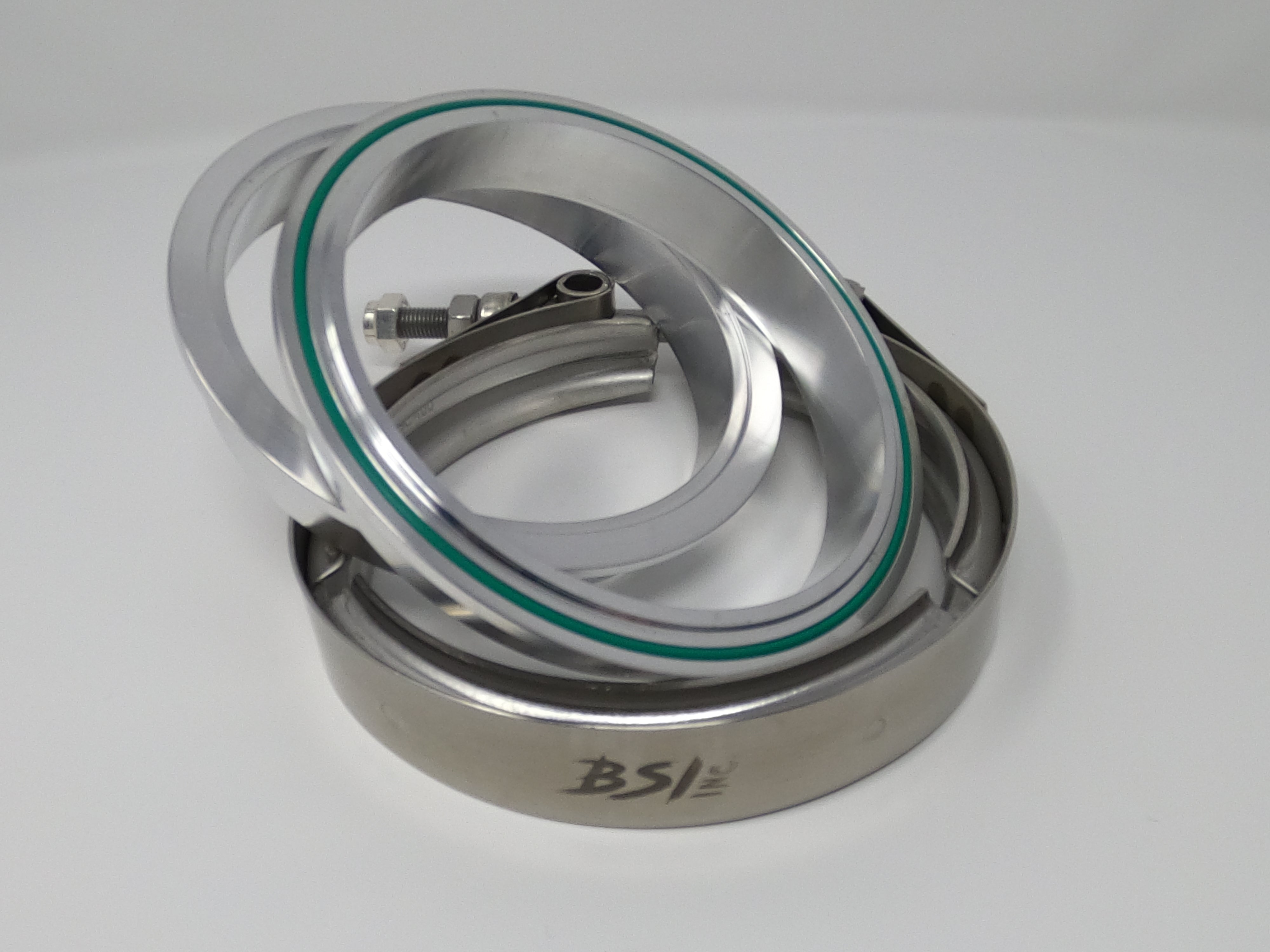

2.5" Aluminum V-Band Flange Assembly with Clamp

2.5" V-Band Flange sets are made from 6061 billet aluminum. The quick-release clamp is made from 304 stainless. Viton O-rings are a standard feature.

blacksheepindustries.ca