Jeez...Trying to get this thing going and , don't know what I'm doing wrong and don't want to mess something up.

Had everything ready to fire up and test this morning. Distributor all set up at #1 tdc compression I'm sure...but ...

Fired the truck up...Heard scary light knocking sounds... Maybe it was diesel sounds....shut it down after a couple of seconds....

truck had been through the lifter cleanings and all that so I figured maybe it was getting settled in... Fired it up again....

Lots of clattering...All lifters were noisy.... Truck was running ok though..... I walked around and listened.... I'm not sure I would say they were all clacking but really loud ticking?..

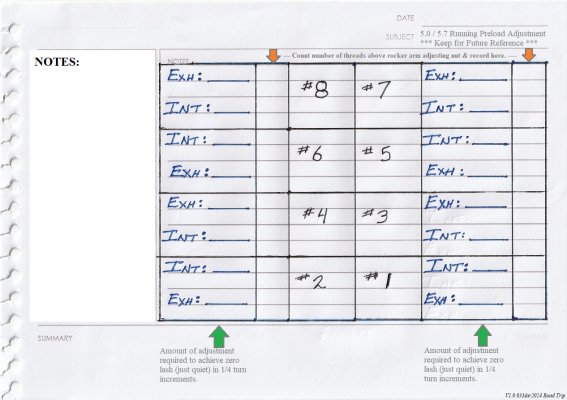

Turned it off. I had done 1/4 turn past zero lash using Schurkey's method. I mean, everything looked about where I thought it should be after finding zero lash and adding a quarter turn. That's where I had it before starting the project and it actually fired up noise free right before I committed to going in....

So I gave everything another quarter turn. Started truck and it was quieter... Was walking around listening where noises were and truck idled down a bit. I assumed it was going into closed loop but temp didn't seem high enough but I didn't have scanner hooked up.

So I shut truck off to set timing. Unplugged timing connector and fired truck up..... ran a little rough but I expected it a little...looked at timing and it was maybe 10 degrees advanced.... ..I went to turn distributor and turned wrong way and advanced it more....Truck sounded good...idled higher..woke up..... but I went back the other way to set to 0 and when I got to zero, the truck died...Now it won't start....

well, if I advance it a little it'll start....and lifters were getting quiet....but as soon as I turn distributor it'll die..

I've checked distributor and made sure I was on tdc #1 compression and the rotor is pointing to number 1 plug on the cap as far as I can tell....

I've heard of people setting in distributor 180 off but don't know what that looks like... I assume the rotor would not be pointing to number 1?

Tempted to shift wires 1 over but it really doesn't look right...

I'm tired so maybe I'm missing something obvious....

Obviously a little cautious because of all the lifters being cleaned and all....

hmm... sound like I'm off on the cap?

The last time I tried starting, I got cranking and then a little backfire out of the throttle body... Nothing big...Just a little pss...

Going to look again but I'm pretty sure it's going to be sitting at # 1 when I get tdc compression again....

is it possible that, because I started at tdc compression when doing Schurkey's method of zero lash, that I rotated 180 degrees to finish and forgot to put another 180 to get back to compression #1 ?

Alright, glad it started right up for you. That's a positive sign.

Re: diesel-like sound. Especially with engines with some miles on them, on a cold start the

pistons will make a discernible diesel-like knocking sound until they grow from combustion heat

to better fit the cylinder bores. According to GM this is not an issue requiring repair. Common

sense tells us that this is yet another reason to drive an engine we care about gently until it's

fully up to operating temps. This is expected behavior, and careful listeners will pick up on this

where most people don't notice anything out of the ordinary?

Re: The concern about the distributor being 180° out? The short answer is that it wouldn't have

started. A dizzy that's set correctly fires the plug towards the top of the compression stroke with

a combustible mix surrounding it. A dizzy that is 180 out (cam degrees, 360 crank degrees) fires

the spark plug towards the top of the exhaust stroke. Unburned mix + exhaust valve open + spark

usually results in backfire out the exhaust pipe. So your running engine confirms that the distributor is

correct, and within a few degrees of optimum?

Re: Preload setting. For everyday operation on the street, year-round, the 1/2 turn setting is the best

overall.

Re: Best initial spark timing. The factory setting is a good starting point. If you want to fine tune to

your engine, the fuel it's being fed, how hard the truck is being used, it's OK to add a couple degrees of

advance and then monitor for signs of spark knock. Depending upon how much carbon is in the combustion

chambers and how well your cooling system is functioning, you could safely add 2-4 degrees and enjoy

more responsive behavior & improved manners. Just don't get greedy.

Put some miles on it and let the ECM relearn what it needs to in order to harmonize the engine bay. (Remember

that you disconnected the battery to redo the intake.)

My hope is that you are close to crossing the finish line with this.

Best of luck --