The salt eating it away to lighten it, along with a perfectly flat driving surface would help.No, she's rust free on the bottom and I would like to keep it that way. I'm willing to drive those speeds though ... for the sake of science of course.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gas Mileage

- Thread starter Nick88

- Start date

-

- Tags

- air fuel fuel economy performance power tbi

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

L31MaxExpress

I'm Awesome

Lean cruise will net 2-3 on its own with the L31 in strictly highway driving and that was pulling a ~6,200 lbs Express van. A L31 is perfectly happy cruising along at 17:1 afr.Any C level or better mpg engineers want to get me an extra 5 mpg on my Tahoe? I'll report the 100% truth. Might be a fun forum thing.

Lean cruise will net 2-3 on its own with the L31 in strictly highway driving and that was pulling a ~6,200 lbs Express van. A L31 is perfectly happy cruising along at 17:1 afr.

Lean burn definitely saves fuel. That's been known since at least Lindbergh crossing the Atlantic.

That would definitely gain some mpg with a whole bunch of rusty weight reduction hahaAre you willing to drive exclusively at the Bonneville Salt Flats?

I plan on possibly switching to a more accurate speedo gear soon, but I really don't mind too much the speed difference. Even if I do I will still use maps to track mileage, theres always some room for error in these trucks speedos and odometers considering they are 40+ years old, hell mine jumps up and down like it's doing jumping jacks under 10-15 mphMy dad and I checked the odometer on that old 83 back when interstates frequently had mile posts years before cheap GPS was even a thing. The factory tire size was P225/75R15 and it had P235/75R15s on it for years. IIRC that van actually went nearly 17 miles for every 16 miles the odometer logged, speedo was off a bit too, 70 mph was like 66 mph on the speedo. I also prefer using GPS log for mileage driven as most vehicles are off a bit. Those old mileage logs were purely off the odometer. 17/16 = 1.0625 x 17.25 = 18.32 mpg corrected for odometer error.

L31MaxExpress

I'm Awesome

Interesting fact, Lindbergh was a civilian contractor in WW2, brough in to help get the P38s the range to fly longer Pacific missions. He leaned those Allison V12s out, ran with the prop at a pitch that ran them at a lower rpm than the Allison engineers thought was safe. After something like 500 flight hours the engines were pulled apart and found no undue wear. Running leaner had the side effect of also helping prevent lead fuel plug fouling.Lean burn definitely saves fuel. That's been known since at least Lindbergh crossing the Atlantic.

L31MaxExpress

I'm Awesome

I forgot to mention a few specifics that are in writing.

Lindberg knew a thing or two about fuel savings. It was picked up on, when the rest of the squardron he was flying with was coming home with empty tanks and he still had ~30% of his fuel onboard. They were teaching the pilots to cruise at 2,200-2,400 rpm, auto-rich mixture and 24 in/hg manifold pressure. In the aviation world they call that a square setup for whatever reason. Linberg was flying at 1,600 rpm, mixture in auto-lean and closer to 30 in/hg manifold pressure to maintain his speed. He essentially shifted into overdrive and went into lean cruise compared to the other pilots. I know later in the war with all the island hopping they ran as little as 1,400 rpm to decrease the fuel burn even more for longer range.

I have read a lot over the years in aviation journals on what they have termed "Lean of Peak" engine operation.

Lindberg knew a thing or two about fuel savings. It was picked up on, when the rest of the squardron he was flying with was coming home with empty tanks and he still had ~30% of his fuel onboard. They were teaching the pilots to cruise at 2,200-2,400 rpm, auto-rich mixture and 24 in/hg manifold pressure. In the aviation world they call that a square setup for whatever reason. Linberg was flying at 1,600 rpm, mixture in auto-lean and closer to 30 in/hg manifold pressure to maintain his speed. He essentially shifted into overdrive and went into lean cruise compared to the other pilots. I know later in the war with all the island hopping they ran as little as 1,400 rpm to decrease the fuel burn even more for longer range.

I have read a lot over the years in aviation journals on what they have termed "Lean of Peak" engine operation.

I believe that during WW2 the RAF had to instil the above in their Spitfire pilots. I think it was condensed into a saying (though I can't remember what it was) and made into a poster for display at the bases. It was along the lines that observing the high prop pitch with low rpm regime could be the difference between making it back to base - or not.I forgot to mention a few specifics that are in writing.

Lindberg knew a thing or two about fuel savings. It was picked up on, when the rest of the squardron he was flying with was coming home with empty tanks and he still had ~30% of his fuel onboard. They were teaching the pilots to cruise at 2,200-2,400 rpm, auto-rich mixture and 24 in/hg manifold pressure. In the aviation world they call that a square setup for whatever reason. Linberg was flying at 1,600 rpm, mixture in auto-lean and closer to 30 in/hg manifold pressure to maintain his speed. He essentially shifted into overdrive and went into lean cruise compared to the other pilots. I know later in the war with all the island hopping they ran as little as 1,400 rpm to decrease the fuel burn even more for longer range.

I have read a lot over the years in aviation journals on what they have termed "Lean of Peak" engine operation.

I forgot to mention a few specifics that are in writing.

Lindberg knew a thing or two about fuel savings. It was picked up on, when the rest of the squardron he was flying with was coming home with empty tanks and he still had ~30% of his fuel onboard. They were teaching the pilots to cruise at 2,200-2,400 rpm, auto-rich mixture and 24 in/hg manifold pressure. In the aviation world they call that a square setup for whatever reason. Linberg was flying at 1,600 rpm, mixture in auto-lean and closer to 30 in/hg manifold pressure to maintain his speed. He essentially shifted into overdrive and went into lean cruise compared to the other pilots. I know later in the war with all the island hopping they ran as little as 1,400 rpm to decrease the fuel burn even more for longer range.

I have read a lot over the years in aviation journals on what they have termed "Lean of Peak" engine operation.

Dude,

*Congratulations* -- you are the very first person I've met in my travels who is also familiar with the whole "Lean of Peak" subject.

Back when I was driving a factory lean-burn '92 Civic VX, I was scouring the interwebs for anything/everything on lean burn

theory, and started reading about this 35,000 hour 747 pilot named John Deakin, and this whole Lean of Peak operation on

piston aircraft engines. Here's a page where some old Pan Am pilots were discussing the difficult max-range island hops

while ferrying planes during WWII: (Stretching the fuel over the oceans while keeping the cylinder head temps healthy)

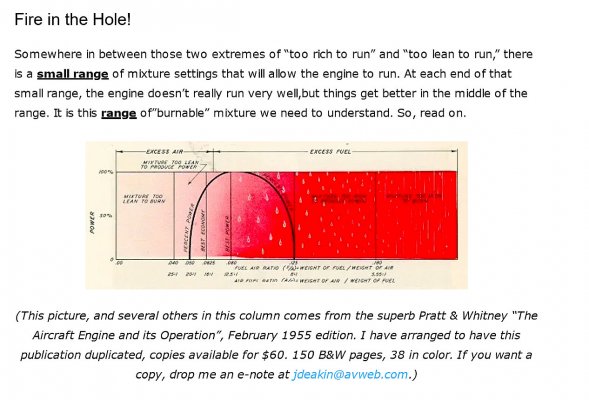

Here's a well-written article by a pilot with specific data comparing normal Rich of Peak vs Lean of Peak operation: (Lean of Peak - power vs savings)

****

In my last theory post on all this (reply #79) I covered the first 2 areas of the MPG subject, but only alluded to the more radical

(some say controversial) Aviation stuff having to do with running carefully balanced FI aircraft engines leaned out past peak

combustion temps to the point where the mixture is lean enough that it runs 50°-75° cooler. You do lose some power as

compared to the normal 50°-75° Rich of Peak combustion temps...but the minor loss is more than made up for by the

improved fuel efficiency.

The more I've studied it, the more it seems to add up. Going back to that previous reply, the first area was just getting

your engine to do the least amount of work by being mindful of all the parasitic losses and how to minimize them. The

second area was where you modernized/optimized your engine using parts bin engineering from newer technology powertrains.

(0411 ECUs, roller lifters, et all)

Well, this Lean of Peak combustion temperature operation is where we depart from what we were taught in school and end up

going a lot deeper into internal combustion theory.

Let me stop for a moment and set the table. Everyone thinks that the compression ratio between gasoline & diesel engines

is why there's such an efficiency difference, especially when towing. The compression does make a difference, but it's only

part of the answer. The real answer is that diesel engines don't experience nearly the pumping losses of gasoline engines simply

because they do NOT use a throttle plate to restrict airflow into the engine. To us gasoline engine mechanics, it's amazing to

watch diesels run from barely ticking over at idle all the way to full rated output, all the while with the (imaginary) throttle wide open. (!)

It's all done by varying the quantity of fuel injected into the cylinders while the All U Can Eat intake is s*cking it all up.

I've personally experienced firsthand the superior highway towing economy in my buddy's old Big Kahuna diesel.

(Opportunistically sold during Covid craziness.) Guess what? Despite being well maintained, various post-warranty $$$ sensor

failures always seemed to eat up any fuel saving -- and once you factored in the $6/gallon diesel at the time, the ROI for a private

citizen was more like owning a boat on wheels than a work truck. :-( Sure, there's no doubt that the truck could do a lot of work,

but the overall total cost of ownership was pretty steep.

...But I digress. The point I was trying to make is that all us carb guys striving for max highway efficiency were trying to keep the

intake manifold vacuum as high as possible, in order to ensure that the power valve would stay shut during cruise conditions.

Instead, we should have been clamoring for a MAF-based EFI so that we could have complete control over the A/F mixture at all

possible engine speeds and loads, so that low manifold vacuum is no longer to be feared as triggering the opening of a purely

mechanical spring-calibrated power valve in the carb.

Instead, we can now embrace low manifold intake manifold vacuum during lean cruise as confirmation of a successful powertrain

combo that is minimizing gasoline engine pumping losses. As long as the thing still drives right. (Note: to see what the old school

rule of thumb looked like, see the attached for a couple of old optional factory 'economizer' gauges plus a nice vac/boost gauge

I've used on past projects.)

As a matter of fact, we had a trusted, fast-acting vacuum gauge connected to the 1.0 liter gas motor on the 70mpg 2-seater Insight,

and in 5th at 65 during steady cruise the intake manifold was running within an 1" of atmospheric. Really strange for an old carb head

to see this after thousands of miles of observing 12-15+ inches of vacuum during highway cruise behind a V8. (And a 6-8" rated

power valve in the carb.)

Of course, the common-sense answer is to run a 4.3L with a 5-speed manual and tall gearing highway gearing. I'll bet you that

the intake manifold vacuum at highway speeds would be pretty low, which contributes directly to much lower pumping losses

and better MPG than a 5.0/5.7/7.4 with 3.73 or 4.10 work-oriented gearing.

****

If I were to eschew a common-sense 4.3L solution & instead go for the 'have my cake & eat it too' goal (think 4.3L economy

combined with 7.4 power) and try to emulate what the Lean of Peak pilots are doing, I would add 8 thermocouples to the exhaust,

and whenever I engage the cruise control I would switch to the EGTs as my primary feedback loop, and have the 0411 operating

the injectors so that the engine was running 50°-75° lower/leaner than peak combustion temps. Voila! -- it would take more throttle to

run this lean yet still maintain the desired speed, so the intake manifold vacuum would be less, lowering pumping losses, and thereby

improving MPG. By running the same combustion temps as stock, my NOx won't go off the scale.

Taking this to the logical extreme, a correctly-sized turbo could be employed to maximize energy recovery -- essentially using the

energy of the exhaust to further lower intake manifold vacuum for a given power output. Think boost for economy instead of

power. I've worked with a couple of turbocharged sports cars, and they would often be on the cruise control with either near-zero vacuum

or even a couple of lbs of boost showing on the intake. And they always just floated up the hills, even in top gear. The newer

MAF-based EFI systems don't seem to get lost in various low-vacuum scenarios.

The final optimization would be a 6-speed manual and changing from the stock 4.11 gears to taller 3.42 gears? Ideally you would end up

at a low rpm with the turbo allowing the big block to stay in overdrive 6th while pulling the grade lightly loaded...and overdrive 5th when

you're towing/hauling? (I paid close attention to how the Big Kahuna worked at highway speeds with a car trailer behind it, and the rpms

were low while at the same time the boost was up, and the resulting 'hard at work' MPG was admittedly impressive.)

Of course it sounds like I'm trying to take my 454 and turn it into a diesel. But I'm not. What I'm trying to describe is achieving

a lean-burn balance that minimizes pumping losses by juggling a combination of all these forces. Given the sheer amount of ink spilled

and word-filled screens written/read over the years, it's easy for a lot of us to describe how to juggle the variables in an engine in order to

make more horsepower and torque for track use via conventional hot-rodding methodology.

Instead, I'm trying to describe a way of minimizing the pumping losses while still developing work truck levels of torque and horsepower.

I've seen gas motors designed to run with no manifold vacuum during highway cruise and return 70 mpg. Of course the whole time I

was driving that gas-sipper I was wishing that I was enjoying the GPM (Grins Per Mile) of the 454 instead. And of course when I'm

driving the chore truck I never had to wear the paper bag over my head like I did when piloting the 2-seater Insight. :0)

****

And for anyone still reading, here's one more link for your reading pleasure. You think the Best Wiper or Best Oil threads create

spirited discussion? Watch aviation dudes try this new methodology on for size: (Lean of Peak detailed discussion with comments)

That's all I got for now. I'll give all this a rest for awhile, but there's this dude named Basjoos, a self-taught backyard aerodynamicist who

was getting 95+ mpg out of what might have been the ugliest boat-tailed car ever driven on the public road. There's some pretty wild

stuff out there once you depart the beaten path, all in the name of max economy...

(Apologies for the length, but I've been carrying this around for awhile, and it's good to finally unload this somewhere. And besides

it's L31ME's fault, he said Lean of Peak first. :0)

Attachments

-

Lean of Peak during WWII - stretching the limits while island hopping in the Pacific -- Genera...jpg381 KB · Views: 49

Lean of Peak during WWII - stretching the limits while island hopping in the Pacific -- Genera...jpg381 KB · Views: 49 -

John Deakin - Pelican's Perch #18 Mixture Magic - AVweb — Mozilla Firefox 5102024 32101 AM.jpg191.2 KB · Views: 49

John Deakin - Pelican's Perch #18 Mixture Magic - AVweb — Mozilla Firefox 5102024 32101 AM.jpg191.2 KB · Views: 49 -

Optional mid-'70s Olds factory economy vacuum gauge.jpg100.4 KB · Views: 26

Optional mid-'70s Olds factory economy vacuum gauge.jpg100.4 KB · Views: 26 -

Working Vtg 1960's Pontiac Factory Manifold Vacuum Gauge Console Dash Mount eBay.jpg220.4 KB · Views: 26

Working Vtg 1960's Pontiac Factory Manifold Vacuum Gauge Console Dash Mount eBay.jpg220.4 KB · Views: 26 -

Autometer 2-116 BOOST & VACUUM, 30 IN HG30 PSI, MECHANICAL, SPORT-COMP.jpg134.3 KB · Views: 25

Autometer 2-116 BOOST & VACUUM, 30 IN HG30 PSI, MECHANICAL, SPORT-COMP.jpg134.3 KB · Views: 25

Last edited:

Worth remembering though that diesel efficiency isn't only from increased CR and minimised pumping losses but is in no small part from the reduced (overall) combustion temperatures due to the considerable excess air which reduces heat loss to coolant.

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 58

- Views

- 3K

- Replies

- 3

- Views

- 884

Members online

- Torchred

- Stormbringer

- Drunkcanuk

- ChrisT2006

- johnckhall

- 96rado

- someotherguy

- jess t

- Tomcat71

- Lance Lara

- Dariusz Salomon

- DirtBag

- SNCTMPL

- 0xDEADBEEF

- Ster1

- PlayingWithTBI

- El Tigre

- reddman6891

- WrenchAndRatchet

- dhworkin

- strikk

- crowfather

- Danimal08

- obsandrade_19

- Sean Buick 76

- Alteca

- The-Distor

- David Hazel

- fancyTBI

- Tombbo

- T3B3

- Jobpartson009

- BRANDON GREENE

- the_elegant_fox

- John Moore

- Jason Warrum

- Supercharged111

- Remodelmaster

- Dame Dog

- 1998_K1500_Sub

- kdhs10

- whynotzoiderg

- Caman96

- termite

- bigblockburb

- movietvet

- mm1077

- 94ChevyZ71

- Pakoluna94

- 98tahoe4dr

Total: 1,022 (members: 75, guests: 947)