I have a 1988 350 TBI vin K. Little back story, my old ECM was shot and wouldn’t recognize a faulty egr. I found the cheap egr I had was failed and could not hold vacuum, so I replaced it with a new AC Delco that I confirmed works perfectly. I resistance tested solenoid and verified voltage at connector. I checked vacuum lines and confirmed no leaks. I swapped in a new ECM temporarily to fix the old and it popped code 32, which I never got before due to old bad ECM. I figured it might be the ECM so I popped in the new one once it finally came in from being ordered but I still got the code. Following this, I completely cleaned the EGR, tons of carb cleaner in the intake EGR hole and I snaked a wire around a few times in case anything is in there. I ran the truck with no EGR for a few seconds and it shot out black carbon everywhere. So I cleaned it a few more times just in case and it stayed away for a few days. I was on the parkway today and sure enough it came back. I have a 3 inch exhaust cutout directly behind the exhaust factory Y-Pipe. I have read that free flowing exhausts can cause this issue. Does anyone know an easy way to keep the free flowing exhaust but not get the code anymore? The truck gets much much better mileage with the cutout open, hence why I want to keep it. Any help is appreciated.

Greetings Nick88,

In order to gain some insight when diagnosing why your computer is throwing a code I find it helpful to read the

GM Service Manual writeup as to what criteria has to be met before the test is run while you are driving.

We can then infer why a solid failure may seem to be intermittent, as well as what else has to be working properly

in a supporting role, or end up becoming the straw that broke the diag's back.

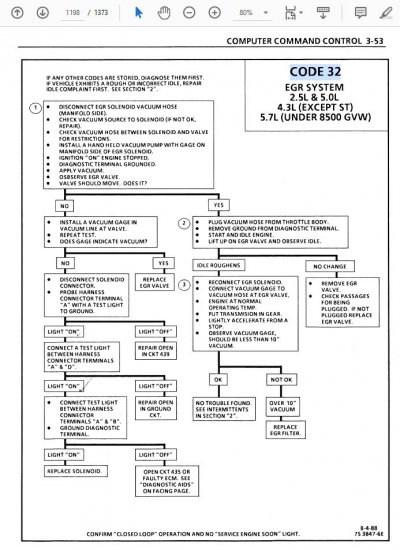

Given the above, let's check out the first page of the Code 32 write up in the '89 FSM:

You must be registered for see images attach

(Excerpt from FSM sourced from here: '88+ GMT400 Factory Service Manuals)

So the way I read it, in order to meet all the criteria for this self-diagnostic to run, we have to drive

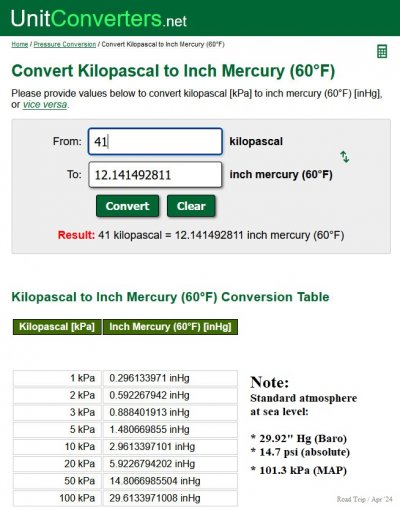

the truck above 50mph, maintain a steady throttle with a MAP reading of 41-50 kPa. So depending upon how

you use your GMT400, you may run a few errands over a couple of days and never quite string these 3 variables

together long enough for the test to run?

In other words, you getting on the parkway must have finally given the opportunity for this test to run/fail.

As for how the computer infers that the EGR valve is operating, during the test it shuts off the EGR and then

looks for a change in the 'fuel integrator counts'. (That's OBD1 speak, in the land of OBD2 we refer to this as

short term fuel trims. Note: One of the supposed benefits of the OBD2 rules is that all the manufacturers had to

standardize on industry-wide defined terms instead of each OEM using unique terminology in their training/FSMs...

supposedly makes it easier for the mechanics in the independent shops to work across different brands.)

In English, as a troubleshooter you now realize that the coders are relying upon a functional O2 sensor to be sensitive

enough to detect/feedback these changes back to the computer. IF this was my vehicle, and the O2 sensor has

been installed for an unknown length of time, I'd seriously consider changing it as normal maintenance, and if a

fresh O2 sensor helps this test to pass, all the better.

Now of course if your O2 sensor is fully functional and yet the EGR valve can't deliver the inert gas it's supposed to,

then of course the test will fail. You mentioned that the original EGR valve failed a vacuum test, but the new one

passed. Of course the acid test would be to get the truck up to temp, idling, and then using a hand vacuum pump

(Like this) open the EGR valve and verify that you can directly affect the idle. (runs roughly)

IF applying vacuum directly to the EGR valve does not affect the idle, then you need to restore the gas path that

@PlayingWithTBI was describing in reply #4. If applying vacuum directly does affect the idle, then the next check

is to reconnect the EGR valve to the EGR solenoid, and then see if the solenoid is also working as advertised.

****

Hopefully the above will provide you some troubleshooting food for thought. If the EGR valve opening = actual exhaust

gas allowed into the intake, and the O2 sensor isn't too lazy/asleep at the switch to notice the difference and feeding that

back to your new computer, followed by the EGR solenoid being able to stop the EGR operation, then you have the best

chance of getting this to work despite lowering the exhaust back pressure to one side of the EGR valve.

****

And if I do all of the above and I can't get this test to pass? In the interest of science I would concoct some sort of

temporary backpressure hack and see if I can figure out just how many inches of exhaust backpressure it takes to

make the light stay out...and then share that info here for the benefit of the other TBI drivers. :0)

Hope this gives you a few troubleshooting ideas. (See 1st attachment for the factory checks.)

Let us know what you discover.

Best of luck --

Attachments

Last edited: