Replaced MAP sensor TWICE.... keep getting P0108 code. Checked wiring to the sensor and I have proper voltage and continuity and wiring is all good. There is absolutely no room to test sensor on the truck with it plugged in!? Sprayed brake clean and there doesn't seem to be any vacuum leaks, engine rpm didn't change. I used MAP sensors from advance auto and napa.....(CarQuest and Napa Gold). With a somewhat ok scan tool. Live Data was 8.8 inHG for MAP sensor if that helps?!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

97' Silverado 5.7 ext.cab rwd MAP SENSOR

- Thread starter Docs

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

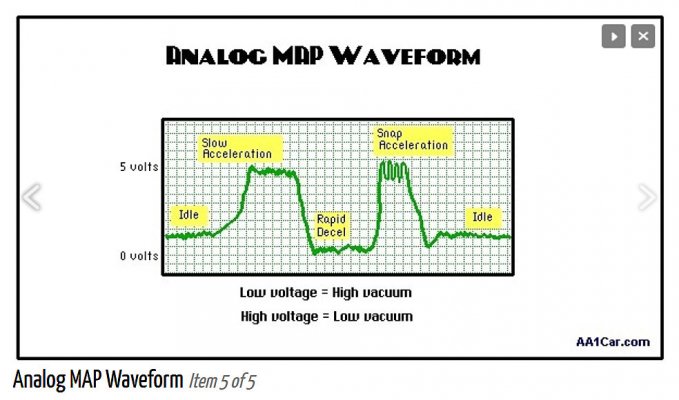

Connect scan tool, drive vehicle. Watch MAP sensor reading as you vary the throttle. The harder the engine is working, the more pressure it should report, and no dropouts or other suspicious readings.

8.8inHg isn't all that high. Did you clear the code at any point, to see if it would come back?

DO NOT EVER (!!!) use aerosol brake cleaner to test for vacuum leaks. A) some of it is non-flammable, so it doesn't cause the engine to surge when it's ingested, and B) some of it that does burn, produces poisonous gas that can FUUK YOU UP.

8.8inHg isn't all that high. Did you clear the code at any point, to see if it would come back?

DO NOT EVER (!!!) use aerosol brake cleaner to test for vacuum leaks. A) some of it is non-flammable, so it doesn't cause the engine to surge when it's ingested, and B) some of it that does burn, produces poisonous gas that can FUUK YOU UP.

Last edited:

someotherguy

Truly Awesome

An UN-LIT propane torch - skinny bottle with the angled nozzle - is great for checking for vacuum leaks. A bit easier to control than spraying liquids around, IMO.

And absolutely, spraying the "good" brake cleaner - the chlorinated solvent type - you burn that stuff and you get phosgene gas, can easily end up in the hospital in very bad shape with permanent damage done.. or even croak. Very no bueno.

Richard

And absolutely, spraying the "good" brake cleaner - the chlorinated solvent type - you burn that stuff and you get phosgene gas, can easily end up in the hospital in very bad shape with permanent damage done.. or even croak. Very no bueno.

Richard

Replaced MAP sensor TWICE.... keep getting P0108 code. Checked wiring to the sensor and I have proper voltage and continuity and wiring is all good. There is absolutely no room to test sensor on the truck with it plugged in!? Sprayed brake clean and there doesn't seem to be any vacuum leaks, engine rpm didn't change. I used MAP sensors from advance auto and napa.....(CarQuest and Napa Gold). With a somewhat ok scan tool. Live Data was 8.8 inHG for MAP sensor if that helps?!

Greetings Docs,

Based upon the specific symptoms you are seeing, this recurring P0108 may give you a specific area to

troubleshoot. I've included the relevant page from a Vortec-era FSM so that we can map all this out &

get a big picture overview of what we're working with.

My first question is about the original DTC that started your repair effort? Was it also a P0108, or was it

a different code? For the moment I'm going to assume that the original code was also a P0108, and the

scenario that we're in is that 2 new MAP sensors didn't change the symptoms. (Note: IF the original code

was different and the new MAP sensors created the P0108 then our approach will be different & we should

start over.)

So my long distance assumption is that the original + 2 replacement MAP sensors all kicked the same P0108 DTC.

According to the FSM, IF the VCM observes the MAP voltage above 4.4 volts for more than 1 second it will kick

the code. As you can see in the red oval, a 5.00v Reference signal is applied to one end (Pin C) of the MAP sensor,

while a sensor ground is applied to the opposite side (Pin A) of the MAP. And depending upon how much/little the

intake manifold vacuum is, a variable voltage is taken off of Pin B and is the input to the "MAP sensor signal"

(pin 21 on connector C2) on the VCM. (See attached for an example of the varying analog output signal that

we'd see if we scoped Pin B.)

Here's the fun part. IF your computer had kicked a P0107, then this = a too low of a voltage out, which would

tell us that the ground was still connected, but we had lost the +5v reference voltage. Instead, you got the P0108,

which meant that instead of the normal ~0.4v <> 4.4v expected normal band of operation, we must have lost the

ground connection on Pin A, so the entire variable resistance shown in the yellow oval floated up to the +5V reference.

And if you poke around in the FSM, there's also a P1106 code which stands for the 'Intermittent MAP Sensor Circuit High Voltage'.

****

So according to the VCM it sounds like you have a fairly persistent issue with the ground to your MAP sensor?

Is it possible that the problem is there when the connector is on the sensor in the installed position, but the

break disappears when you pull the connector in order to make your continuity checks? Was the harness dressed fairly

tight/under stress anywhere in the vicinity?

To prove/dispove the bad connection theory, you may have to backprobe a bit while the MAP sensor is in

the installed position. If you do, just be sure to put the magic repair goo on any piercings after you are done

to preclude internal conductor corrosion down the line.

Q: Is the P0108 the only DTC your computer is kicking? Note that the MAF, Fuel Tank Pressure Sensor, the

TFT & even the fuel pump/sensor are all tied to this VCM sensor ground according to the wiring diagram.

Obviously, if *all* of the above are kicking codes, then the problem is between the splice and the VCM ground

pin.

IF on the other hand, the P0108 is the only code you are seeing, then the problem is somewhere between

Pin A on the MAP sensor and the aforementioned ground splice.

You must be registered for see images attach

Again, all the above is the highest probability failure IF this all started with a P0108, and new parts won't clear the

fault. A different original DTC could well be a different kettle of fish.

Food for thought. Hope this proves helpful. When you discover what ails your GMT400 and you

get it fixed, then please come back and share the wealth with us.

Best of luck with the hunt --

PS - A lower than expected MAP reading (8.8" Hg) would translate to a 'too high' voltage from the sensor,

(see attached) which tends to support the theory that a marginal ground is playing havoc with the operation

of your MAP circuit.

Attachments

Last edited:

Yes.. cleared code and came back Will try going for a drive and watch live data. Thnx....Connect scan tool, drive vehicle. Watch MAP sensor reading as you vary the throttle. The harder the engine is working, the more pressure it should report, and no dropouts or other suspicious readings.

8.8inHg isn't all that high. Did you clear the code at any point, to see if it would come back?

DO NOT EVER (!!!) use aerosol brake cleaner to test for vacuum leaks. A) some of it is non-flammable, so it doesn't cause the engine to surge when it's ingested, and B) some of it that does burn, produces poisonous gas that can FUUK YOU UP.

Similar threads

- Replies

- 1

- Views

- 747

- Replies

- 0

- Views

- 223

- Replies

- 21

- Views

- 1K

Members online

- spoisel

- 11bravo

- retorq

- johnckhall

- WhiteUCF

- rick69

- termite

- jinks67

- greeneyes

- Cadillac Bob

- jasons

- registered-bum

- JD 53

- JDGMC

- Ward

- twoyehaa

- frederik

- msmall

- BuiltToWork

- fastcheaporright

- Road Trip

- tayto

- GMTMark

- Notjoken

- GrimsterGMC

- 2po2watch

- Keeper

- bkgrover

- BeXtreme

- Machlen

- KleenScottsdale

- huskerfan

- Georgiabigfoot

- Harley5425

- trckenthust

- El Tigre

- Drunkcanuk

- ncsticks

- Obs1997

- Canaveral

- Orpedcrow

- fancyTBI

- imkwuzn

- 454cid

- kidwonder

- ugotpwnd

- BLK97OBS

- sbrookens

- Tmags2271

- 94K1500WT

Total: 1,354 (members: 107, guests: 1,247)