Stock type for the lifters you have in there now and no cheap chineseium crap.Any recommendations?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1993 Yukon crate motor hydraulic roller lifter cleaning and adjustment journey - (Solved)

- Thread starter scott2093

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Roller;Stock type for the lifters you have in there now and no cheap chineseium crap.

COMP Cams 850-16 COMP Cams High Energy Hydraulic Roller Lifters | Summit Racing

Free Shipping - COMP Cams High Energy Hydraulic Roller Lifters with qualifying orders of $109. Shop Lifters at Summit Racing.

Flat tappet;

CHEVROLET COMP Cams 812-16 COMP Cams High Energy Hydraulic Lifters | Summit Racing

Free Shipping - COMP Cams High Energy Hydraulic Lifters with qualifying orders of $109. Shop Lifters at Summit Racing.

Any recommendations?

Hi scott2093,

Long term success will require careful sequencing, oil pressure and consumption monitoring, and only then

followed by careful parts selection & replacement.

In English:

1) Discover source of metallic debris in oil and fix that. Can the engine then be decontaminated enough

that the new oil isn't also full of glitter...and more importantly, remains glitter free?

2) Until step #1 is conclusively fixed, I wouldn't introduce any new parts to dirty/contaminated oil.

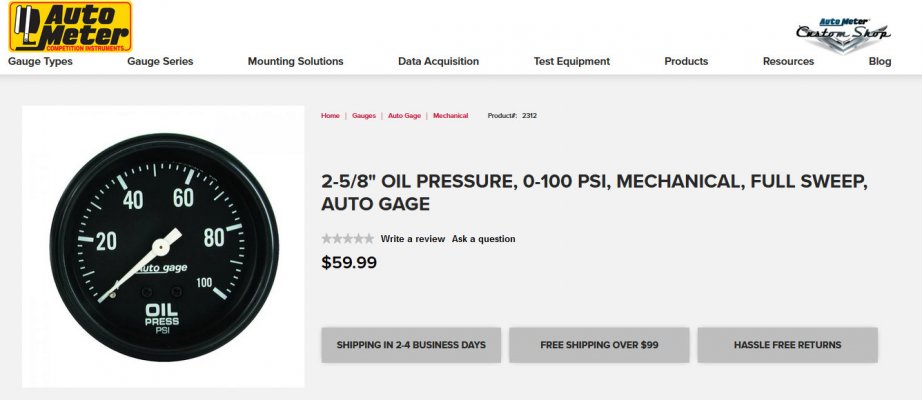

That would be throwing good parts after bad. So, assuming that your engine oil is now staying clean,

I would now monitor the engine with a no-kidding mechanical oil pressure gauge. (See attached for one

possible example.) IF after all this the oil pressure is still well within limits, then we can assume that the

crank main, rod, and also cam bearings haven't worn to the point where the oil pump can't keep up with the required

volume, and will end up not being able to supply the necessary pressure required for reliable, quiet, hydraulic

lifter operation. (!)

3) IF you successfully navigate step #2 also, only then would I look hard for a stock GM roller cam that

will be as compatible with your existing computer as the current cam appears to be.

If we assume that the current roller lifter's internal clearances have been opened up by the metallic debris in

the oil (to the point where they would fail the leakdown timing tests outlined in the old GM FSMs

referred to earlier) ...then I would add 16 matching new GM 'LS7' roller lifters. (Best OEM .842" roller lifters)

Note: In the technical specs they recommend using a .060" preload on these lifters.

****

Thanks to the solid practice & resulting skills that you have acquired, I think that IF everything lines up just

right that you could revive this engine for additional service. Please note I advise that each step be performed

in sequence, and use this as a non-negotiable Go/No-Go approach. (ie: If you can't get the glitter to go

away/stay away in Step #1, then I wouldn't spend any more time/money attempting Step #2 or #3. Period.)

****

By the way, I don't think that you hastened the demise of this motor by attempting to intervene and make things

less noisy. For what it's worth, way back when I tried some Rislone on a noisy motor, and it also didn't provide the

fix I was looking for. (On the other hand, adding a quart of ATF and running the engine for awhile prior to

changing the oil has worked for me on a few occasions.)

But cleaning the lifters one at a time did. Also, your experience with cold preload vs a running preload is similar to my

own. As mentioned elsewhere, a running preload adjustment has always allowed me to make the best of what I have

to work with. Obviously it's not a miracle cure, but for me if someone asks me to try to quiet a newly rebuilt or high

mileage engine, I've always had the best overall success with this (can be messy) method.

And if the engine stays quiet after the adjustment, then we get to judge that motor as healthy. But if the noise returns

after a short while, then we know that something is changing from underneath us, clearance-wise, and we need to

investigate further.

Finally, if we redefine as our primary goal as simply how to maximize how long it takes for a lifter to bleed down if it happens

to stop on top of it's own cam lobe, then assuming that the bleed down rate is the same from barely quiet to almost

bottomed out, then setting the preload as deep as reasonably possible in the total travel available should give you

the longest 'elapsed time until clack' on startup. If a half-turn gives you, say 4 hours on a particular lifter, then setting

that same lifter to 1.5 turns (out of 2 max?) should give you ~12 hours before clacking on startup? You can certainly

try it, but as others have pointed out it would be prudent to first verify the total internal travel available first using a

dial indicator or equivalent.

As for the self-locking nuts, do they still provide adequate 'running torque'? (aka: resistance to turning during adjustment.)

If they are still good, then no worries. But if 1 or more are becoming too easy to turn, then they could back off while

the engine is running over time and create more troubleshooting head-scratching over where is this clacking coming from.

****

I think that this is a prudent approach. It doesn't preclude repairing what you've got, but at the same time it only

allows for spending money on parts *after* the engine proves to you that it is still healthy enough to support those

new parts properly.

Best of luck. Still rootin' for ya keeping your GMT400 on the road, one way or the other.

To paraphrase, remember that all that glitters is not good. At least for motorheads.

:0)

Attachments

Last edited:

I haven't forgotten all my lessons you've shared. I must admit there is a bit of excitement when you bring up new engine replacement..lolIf you can't get the glitter to go

away/stay away in Step #1, then I wouldn't spend any more time/money attempting Step #2 or #3. Period.)

I spent as much time as I could hypothesizing and searching while I had the time this session and, I am disappointed in not being able to feel good about finding where the source of this glitter has been coming from. But I'm not giving up.

I scoped inside of the oil pan last oil change and it was as clean as anyone could hope for and nothing at all in the pickup screen.

Maybe main bearings?idk..

Must say the videos of people just polishing and replacing the bearings looks right up my gluten for punishment way of thinking but, if these things just delay the inevitable for a brief moment in time since the chain of events has already advanced to a far degree,, I'd have to think long and hard about where time would be best spent until then.

. Thank you for sticking with me and helping. I'm certainly feeling much more secure in my thought process and I can't be more grateful for you and everyone else's help...

Last edited:

These are a good buy for roller lifters.

www.summitracing.com

www.summitracing.com

Summit Racing SUM-HT215-16 Summit Racing™ Performance LS7 Hydraulic Lifters | Summit Racing

Free Shipping - Summit Racing™ Performance LS7 Hydraulic Lifters with qualifying orders of $109. Shop Lifters at Summit Racing.

So it seems like my last readjustment to 1 full turn past zero lash made some changes. I've only had 2 random, not always,taps at startup for many driving sessions since. Actually didn't have any at all for the first several trips and was excited but, it returned..booIf you can't find absolute perfection in terms of a stray tap on startup, then if you are

going to err, then please err on the side that gives you the smoothest idle. Simply put,

the more consistently that the valves are closing (and getting rid of the heat that will

burn them if not shed) the smoother the idle. So if 3/4 of a turn preload still gives you

a smooth idle, then let's stay at this setting. And again, if the engine stop lottery puts

the loosest lifter on top of it's cam lobe every so often and you end up with a few taps

on start up, I'm perfectly OK with that.

I noticed that my temp gauge climbs up a bit higher than before now. It'll creep up to 210 before 190 thermostat kicks in...

Is this the heat thing you speak of? Should I be concerned.

Just weird that before I ever attempted lash adjustments in the very beginning, I never had

1) tapping at startup

2) lower oil pressure at idle..

3) the rising heat....

4)glittery oil

maybe I goofed something on my initial cold adjustment in my first attempt way back when this all started and the idle was loping hard...idk...it was such a chaotic process the first time running around doing adjustments, who knows what the heck happened.

I mean, looking over my notes in the thread, one rocker nut had to be loosened 1.5 turns to get past zero lash.... and that's after goofing around several attempts prior....and after several hundred miles of driving....

I do think maybe the tapping is related to air. Tempted to just go with the vertical oil filter adapter to rule out mine having a funky bypass but idk. The 4wd adapters are in rough shape out in the wild and new ones can't be found so the different style with a shorter filter would be the best option I guess....

Could leave well enough alone...Will see if the tapping stays at a couple.... just the heat rise I wanted to make sure was ok... Already know 3/4 turn past zero was giving me random minute long or more taps...

Last edited:

So it seems like my last readjustment to 1 full turn past zero lash made some changes. I've only had 2 taps at startup for many driving sessions since. Actually didn't have any at all for the first several trips and was excited but, it returned..boo

I noticed that my temp gauge climbs up a bit higher than before now. It'll creep up to 210 before 190 thermostat kicks in...

Is this the heat thing you speak of? Should I be concerned.

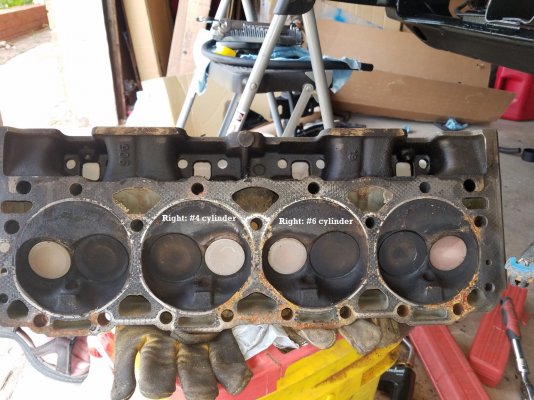

When we were discussing various valve preload settings, my concern was that if the valves were set 'too tight'

and this led to the valves being held off of the seats, then the temperatures of those valves would be set by

the passing gasses instead of the water jacket. (valve seat acting as thermal heat sink between the exhaust valve

and the coolant in the water jacket.)

In English, the exhaust valve is exposed to superheated gasses whenever it's open. (Remember, our O2 sensors

don't wake up until ~600°F, and the old single wire jobs relied solely upon passing exhaust gases to hit these temps.)

Meanwhile, the exhaust seat is close to the same temps as the coolant, several hundred degrees cooler.

(See attached photo for the color of a typical exhaust valve on a modern Vortec engine -- the exhaust valves run *hot*.)

Just weird that before I ever attempted lash adjustments in the very beginning, I never had

1) tapping at startup

2) lower oil pressure at idle..

3) the rising heat....

4)glittery oil

What was your original motivation to attempt the valve preload adjustments? Was it rough running,

or was it a continuously noisy valvetrain while the engine was running? Just trying to figure out if the

metallic debris in the engine oil was starting up prior to your intervention, or if it started afterwards?

BTW, if you were to pick up a new drainpan at Walmart for $2.97, and then clean it after draining

with some furniture polish, then you will be able to better read each draining for debris. (As opposed

to cross-contamination obscuring your analysis.)

maybe I goofed something on my initial cold adjustment in my first attempt way back when this all started and the idle was loping hard...idk...it was such a chaotic process the first time running around doing adjustments, who knows what the heck happened

I mean, looking over my notes in the thread, one rocker nut had to be loosened 1.5 turns to get past zero lash.... and that's after goofing around several attempts prior....and after several hundred miles of driving....

It's hard to assign causation when dealing with a reman motor after delivering 15 years of service.

And if it was your destiny to wound an engine while traversing the learning curve, better an old

engine near it's end of service life vs. a brand new $$$$ crate motor. Don't beat yourself up too

much. No free lunch, and for that matter, no free learning. Learning how to optimize the preload

on a SBC valvetrain is a skill that not too many normal folks can truthfully claim to have mastered. (!)

I do think maybe the tapping is related to air. Tempted to just go with the vertical oil filter adapter to rule out mine having a funky bypass but idk. The 4wd adapters are in rough shape out in the wild and new ones can't be found so the different style with a shorter filter would be the best option I guess....

I concur, air in the oil explains both when you observe the tapping vs when you don't. If this truck was

mine, I would seriously consider running the normal vertical oil filter adapter + the shorter filter. I'd look at this

as a low-cost way of eliminating another variable in what's affecting the oil already in the distribution system

after the engine sits immobile after shutdown.

And IF the shorter filter were to fix the issue, then if I'm changing my oil on 5K intervals, I might change

the filter halfway through. (ie: Oil every 5000 miles, but filter every 2500 miles) NOTE: This is only if I was

concerned about how much less dirt the shorter filter could bank as compared to a longer filter? As in your

engine is generating enough debris in the engine oil to cause an actual pressure loss across the filter? In

other words, I think that a clean shorter filter is a viable option for your 4WD truck, and it's easy to

swap in another filter if you are seeing a pressure drop on a high resolution oil pressure gauge.

Could leave well enough alone...Will see if the tapping stays at a couple.... just the heat rise I wanted to make sure was ok... Already know 3/4 turn past zero was giving me random minute long or more taps...

I've been thinking about all this -- troubleshooting our troubleshooting...meta-troubleshooting? :0)

Seriously, somewhere between trying something just because vs analysis leading to paralysis, there is

an optimum where we maximize the data extracted from each change performed. As a troubleshooter,

IF you can make a change, predict the outcome, and your prediction is correct, *then* you are in control.

But if your prediction is wrong, you have learned that your understanding is incomplete.

It took me years as a paid troubleshooter to figure this out. On easy problems on simple systems that

always broke a certain way, I could predict right from the beginning what would work vs what would leave

us empty-handed. On really difficult systems that had several different possible ways of failing, I would

analyze the situation, choose the highest probability fix, predict the outcome, run the tests and observe

the results.

And when the results were negative, then I knew immediately that my understanding of the failure was

incomplete at best. And I would keep score, for knowing what it wasn't was just as valuable as knowing

what the root cause was.

So what is the point that I'm trying to make? Instead of just leaving well enough alone, how about we

change that to "with this current 1 turn preload + factory 4WD oil filter adapter, what is the ratio of

quiet starts to clattery starts?" For the sake of argument, you decide that it's 2 noisy starts out of

10 total, for a 20% noisy startup. Of course, the longer you drive between changes, the more accurate

your data capture.

So let's say that in a week you average 50 starts. 10 starts involved short term clattering, which gives us

the 20% failure rate. You now change *1* variable, and then drive the truck another week without changing

anything else. Let's say that you pull the factory 4WD oil filter adapter, and run a new vertical thread on setup

with a shorter filter. And after the 2nd week you still have intermittent failures, but it was only 5 times in

50 starts, so now you have a net improvement to a 10% failure rate.

Meanwhile, you are still working on getting the metallic debris out of your engine oil, further improving your

chances at fixing the noise in this engine. You could then try different engine oils, filters, etc., until you

you figure out what *this* engine wants in order to minimize the valvetrain noise on startup.

Still not perfect, but at the same time you do end up with a better understanding of what you are working with.

The key is to not rely upon your memory, but to keep really good records using a small notebook stashed in

the glovebox.

****

One last thing having to do with rising coolant temps. It all depends upon ambient temps, how hard you are

working your motor, and whether or not things are moving around on us. (For example, IF the coolant system

starts to show signs of disappearing coolant, then maybe a long-suffering head gasket is starting to give way.

As long as the engine doesn't drastically change it's oil consumption or start using coolant we can continue to

focus on the valvetrain noise on initial startup. And realize that there are lots of people driving around SBCs with

valvetrains that are noisy 100% of the time. At least your valvetrain is quiet and running smoothly once the air

is gone and the engine is all warmed up.

Attachments

Last edited:

Silver lining that my O2 sensor is alive?lolIn English, the exhaust valve is exposed to superheated gasses whenever it's open. (Remember, our O2 sensors

don't wake up until ~600°F, and the old single wire jobs relied solely upon passing exhaust gases to hit these temps.)

Meanwhile, the exhaust seat is close to the same temps as the coolant, several hundred degrees cooler.

(See attached photo for the color of a typical exhaust valve on a modern engine.)

Truck is feeling pretty good....

I actually logged in because I wanted to ramble so I didn't forget my recent thoughts about the beginning of this. So it wasn't planning to be a question as much as notes. But since you asked..What was your original motivation to attempt the valve preload adjustments? Was it rough running,

or was it a noisy valvetrain? Just trying to figure out if the metallic debris in the engine oil was starting

up prior to your intervention, or if it started afterwards?

For several months leading up to me addressing my intake gaskets I was getting some weird rattle from the engine somewhere anytime I was cruising at a reasonable speed or slower through the neighborhood when I would let off the throttle and it would continue while stopped for a few seconds. Accelerating would make it disappear. It would still happen if I heard the noise and put it in neutral while coasting, and would disappear if I gave it throttle... Like a loose chain, coin in a can spinning around... Didn't always happen. Would actually happen at startup sometimes.

I could never get under the truck to find the noise because it was so random and would have a mind of it's own and stop as soon as I tried finding it.

Before addressing the intake gaskets, I pulled the bellhousing inspection cover and checked the torque on the blots to the converter and inspected as best I could. Didn't see anything but it would have been nice to see what the area looked like running . Just didn't want to put the exhaust back just for a test because it was such a pita and my time was limited. I even put a new starter in just because I thought maybe it could have been related but it wasn't. Still happened.

I got lucky one day and realized it sounded like it was coming from passenger side in the engine somewhere...... never could narrow it down because of it's randomness....but I could start the truck and sometimes it would do the rattle... and caught it enough to narrow it down to passenger side of engine....even checked exhaust shields.....

So I addressed the intake gaskets and tried the valve adjustments and haven't heard that sound since. 100% it has gone and 100% it correlates to when I did the intake gaskets and attempted valve adjustments. Carbon chunk? Hopefully but not convinced....

The very first valve adjustments is what I wanted to note here.

Let me start by saying I am not 100% sure about if my oil looked funky before this but, unfortunately it sure feels like I would have noticed because it was pretty obvious artwork that was made and I'm usually looking just because. I feel like I would have definitely noticed before. And oil was changed just before all of this. A switch to synthetic 5w30 from conventional 10w30 for a decade. And a bottle of Rislone hoping it would help that weird rattle...Didn't know what I was dealing with so decided to make all of those changes to see if there were any results. There wasn't. So it was pretty fresh oil at the time I opened the intake up...

A side note- I'm positive it isn't contamination of the change pan. My last recent oil change to Mobil 1 and Mobil 1 filter, same swirly thing with the oil, but not as noticeable for some reason I want to say, and the filter had it in there too when I dumped it. Cut the filter open and there wasn't anything in it. Looked clean.

When I did this last adjustment, I could see a puddle in the rocker area and when I stirred it, I could see streaking.. Put a magnet in the puddle and got nothing.

Back to the first time ever adjusting valve lash.... actually referencing a thread I hijacked at the start of this before starting this thread.....

I did the factory service manual method. TDC compression...loosen one set of rocker nuts (can't recite without looking) to get lash, removed lash by shaking up and down...felt pretty confident about it, then I went 1/2 turn instead of 1 full turn just to be safe and after reading some recommendations.

Then I rotated to the timing mark again and repeated for the other set of valves.....

Put everything back together and struggled with getting dizzy right. Some starting issues... Got that sorted but the truck was loping real bad..wump wump wump idle....revved nicely but it wasn't idling normal.....

Why I thought? 1/2 turn should have been safe.....

When I put it in gear it really loped hard and I heard a couple knocks....shut off truck.....

Started truck and did a running adjustment and put things at 1/4 turn past zero lash...Fixed the loping idle....noticed when I'd try to go half turn, loping would come back....

also noted I was confused about the clacking settling to quiet before I had a chance to tighten rocker nut but I was fast and loose with this process and didn't really pay enough attention or give all the lifters time to settle. But some I did. What a mess ...

So there I am at 1/4 turn past zero lash. Bugged and confused as to why I only could feel like 1/4 turn was as much as the truck would like. But it ran great....(of course now I know after getting more educated and adjusting valves after, that some took 1.5 turns to get lash so I obviously wasn't at 1/4 turn here..They were all over the place.... hundreds of miles driven like this......truck ran great..lol just the tapping at startup......)

Then I started this thread because I had some smoke coming out of the tail pipe.....but before the hundreds of miles of driving to be clear.....started this thread when everything was at the 1/4 turn past zero lash (or I thought)

today.......

Truck has been running great where it's at at 1 turn past zero.... Hardly any taps. Think I may have had 1 startup earlier this evening with 2 taps and that was it for the day.....

The resonance thing, the chirping or whatever I call it, still concerns me...\\\ not noticeable unless you listen for it...but once you do, it's unmistakable.....

Oil pressure is good. Probably 60 at startup (3 tics past 40) ...stays around 40 or over driving around....2 or 3 tics below 40 when idling.... used to never get that low...but switched to lighter oil and synthetic and have all these new valve adjustments so maybe ok......

Been salivating over the talks of a bypass filter... if nothing more than a hail mary to help for now..... Pretty pricey.....And IF the shorter filter were to fix the issue, then if I'm changing my oil on 5K intervals, I might change

the filter halfway through. (ie: Oil ever 5000 miles, but filter every 2500 miles) NOTE: This is only if I was

concerned about how much less dirt the shorter filter could bank as compared to a longer filter? In other

words, I think that a clean shorter filter is a viable option for your 4WD truck.

Not sure anyone's running the Lubrication Specialties Frantz but they're less pricey... tempting...impressive data.....

And want an oil pressure gauge....

need to figure all of that out...

all while wondering if my main bearings are grinding away....cam bearings...idk...that resonance is something I'm concerned with.... I don't hear anything down in the pan.....coming from lifter valley if I had to guess......

But truck is running great.....oil and coolant levels looking good....

Sorry for rambling...Really didn't want to get too far without condensing the beginnings....this should actually be the first post in this thread I guess....

Last edited:

I had brought up in the lounge that there's a young guy who works at Autozone that has a 95 gmt...He let me look at at and he fired up the truck.I'm not up on my SBC factory aluminum valve covers anymore, but I wouldn't

be surprised that a set from a '92 Corvette that would fit your truck are out

there somewhere. (Just from the perspective of an slight audible difference

in sonic signature...but unless you found a pair in the Treasure Yard or a yard

sale for a song, I absolutely wouldn't go there.)

It was then I realized how broken mine sounded...lol

I swear the exhaust drowned out any sound of the motor it was so quiet. And the exhaust wasn't obnoxious, just nice tone. Same motor as mine..no vortec...

He has the Vette valve covers....

Looking around just for kicks of course..lol, I see some of them don't have the deflector shields under the openings. Those must be important I'm sure... I see the deflectors here

TPI Valve Cover CENTER Bolt w/ Emblem LH Driver OEM 1986 C4 Corvette - EXCELLENT | eBay

Find many great new & used options and get the best deals for TPI Valve Cover CENTER Bolt w/ Emblem LH Driver OEM 1986 C4 Corvette - EXCELLENT at the best online prices at eBay! Free shipping for many products!

www.ebay.com

I think he said his were from an 88... but he had mentioned older when referencing what his Dad told him to get.....

Attachments

Staff online

-

df2x44L60E Destroyer

Members online

- fancyTBI

- df2x4

- 1998_K1500_Sub

- someotherguy

- Murphdawg19

- Dentc

- Tmags2271

- johnckhall

- Orpedcrow

- scott2093

- termite

- Hipster

- FNolen13

- brianblanton

- Zack8

- rebelyell

- Nad_Yvalhosert

- skylark

- dunejunkee

- Alteca

- Z71Hobbs

- GrimsterGMC

- slb21f67

- BNielsen

- Jaydenk

- 454cid

- SableSlayer

- WAM62

- Zulu Kono

- Cherryred98

- TonyM

- green961500

- Allen12762

- JBis

- Carlaisle

- 454C2500Longbed

- Nephrodoc

- Corbell

- WindsorWilly

- Sean Buick 76

- crusty

- PlayingWithTBI

- RRRICHIES

- MARKD

- chewyhughey

- ivankelly

- heyitzjoel

- Caman96

- Mobdraco

- Scooterwrench

Total: 1,787 (members: 67, guests: 1,720)