ChrsLytn

OBS Enthusiast

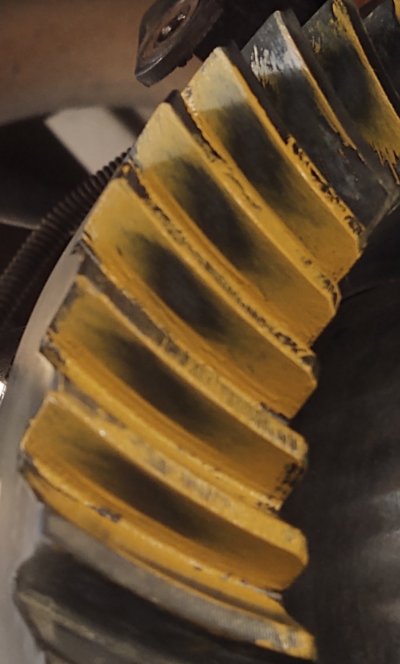

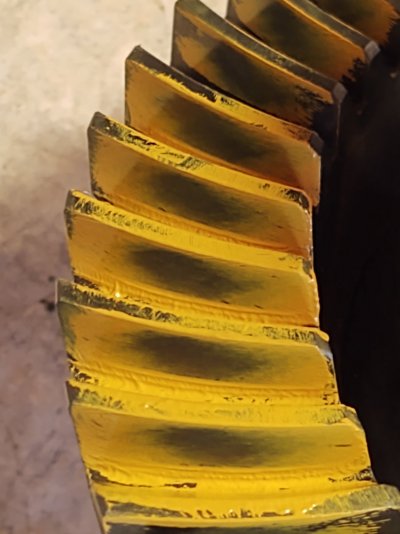

98 K1500 8.5" 10 bolt 3.73

I got new carrier, ring and pinion.

I put the original shim, .0037 I believe on the new pinion and pressed bearing on.

I've been talking with tech support at Yukon but have been unable to get them since Wednesday before Thanksgiving.

Assuming these patterns were good, I have a backlash of 13. I guess that means I would need maybe .002 more shim on the pinion to move it closer to the ring.

If the pattern is good I don't need to change anything on the carrier.

And if that's the case I should try to save the new pinion bearing and make it a set up bearing and get another new pinion bearing or hope .002 will correct the backlash and put bearing back on?

If I get same brand of pinion bearing is the new race I've already put in ok to run?

This is the first one I've done and don't want to f*** it up. And I don't see it as a viable hobby in the future.

Thanks for your time

Thanks for your time and wisdom.

I got new carrier, ring and pinion.

I put the original shim, .0037 I believe on the new pinion and pressed bearing on.

I've been talking with tech support at Yukon but have been unable to get them since Wednesday before Thanksgiving.

Assuming these patterns were good, I have a backlash of 13. I guess that means I would need maybe .002 more shim on the pinion to move it closer to the ring.

If the pattern is good I don't need to change anything on the carrier.

And if that's the case I should try to save the new pinion bearing and make it a set up bearing and get another new pinion bearing or hope .002 will correct the backlash and put bearing back on?

If I get same brand of pinion bearing is the new race I've already put in ok to run?

This is the first one I've done and don't want to f*** it up. And I don't see it as a viable hobby in the future.

Thanks for your time

Thanks for your time and wisdom.