Rustjunky67

I'm Awesome

Hi everyone, so in my last post regarding my camshaft distributor drive gear, the picture I had was from the overhead view looking down hole....

After lots of thought and reading and reading and thinking and reading etc, I ordered a flat tappet basically stock replacement (I know I know but $$) with lifters and timing set. Elgin E-274-s, Elgin hl 1817s, and cloyes 3023 double roller....

While waiting for it, I of course went down the cam/lifter failure rabbit hole while doing some other clean up and maintenance items..... needless to say now scared to death to have this happen to me (remember I'm at the never-even-taken-rocker-covers-off-an-engine-before pay grade).....

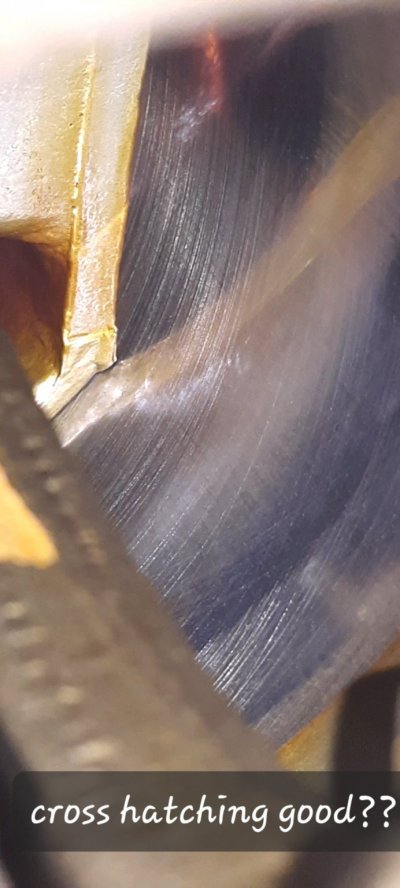

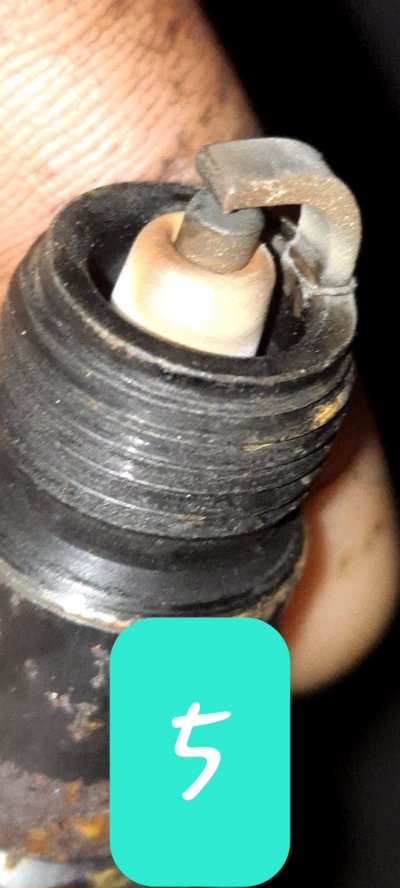

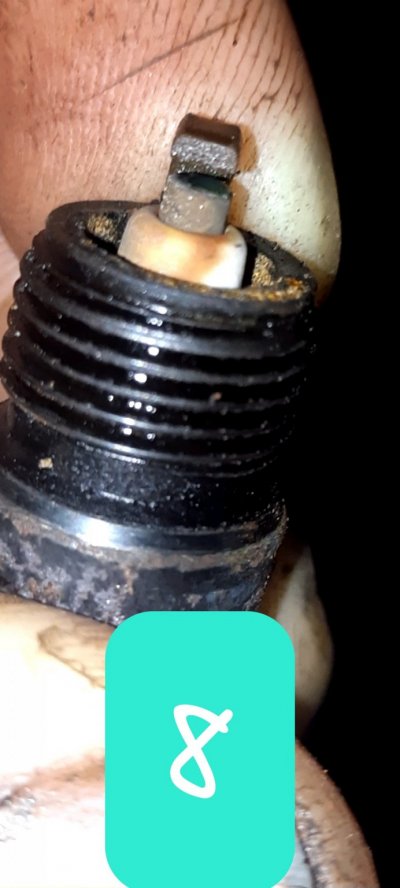

Ok so to get to the point, after FINALLY getting oil pan out (what were those engineers freaking thinking lol), these are some pics from that view...I have plenty more if needed....

But the gear doesn't look nearly like what I expected to see, maybe it was the overhead angle that was causing the original picture to appear as worn as it looked......

I would like to ask if anyone sees anything that needs to be addressed, anything that's not right, or potentially could be a concern, anything that warrants immediate "cease-and-desist further work and replace motor", advice, criticism, or otherwise..... I would LOVE to get anther 350k on this old girl if I can.....

I couldn't find any rule addressing too many pics so I apologize if it's too much.....

Thanks in advance!!

After lots of thought and reading and reading and thinking and reading etc, I ordered a flat tappet basically stock replacement (I know I know but $$) with lifters and timing set. Elgin E-274-s, Elgin hl 1817s, and cloyes 3023 double roller....

While waiting for it, I of course went down the cam/lifter failure rabbit hole while doing some other clean up and maintenance items..... needless to say now scared to death to have this happen to me (remember I'm at the never-even-taken-rocker-covers-off-an-engine-before pay grade).....

Ok so to get to the point, after FINALLY getting oil pan out (what were those engineers freaking thinking lol), these are some pics from that view...I have plenty more if needed....

But the gear doesn't look nearly like what I expected to see, maybe it was the overhead angle that was causing the original picture to appear as worn as it looked......

I would like to ask if anyone sees anything that needs to be addressed, anything that's not right, or potentially could be a concern, anything that warrants immediate "cease-and-desist further work and replace motor", advice, criticism, or otherwise..... I would LOVE to get anther 350k on this old girl if I can.....

I couldn't find any rule addressing too many pics so I apologize if it's too much.....

Thanks in advance!!

Attachments

Last edited: