Hi, new here. I apologise in advanced for a long post. I joined this forum just for this thread! Awesome info and I have a ton of reading to get caught up. I have a 97 K3500 extended cab dually with 232,000 hard miles on the original 7.4l engine. It has the usual problems - leaks, down on power, hard hot starts. I decided to buy a second engine to build up and swap in. After a few calls on craigslist, I found a complete 99 7.4 from a rolled suburban with 30,000 miles, in storage for 15 years, and got it for $1,200.

I took it apart to see how good it was and to replace the seals if nothing else. It was in fact very low miles, but there was strange, spotty wear on the main and rod bearings that I can't figure out, like maybe metal particles or chips were caught under the bearings at the factory. I can't leave anything alone, so that was all I needed to go off. I decided to do a light hone and re-ring with the stock pistons, get the crank reground, the rods resized, do some port and chamber work, then throw in a cam, springs, and adjustable roller rockers.

The crank counterweights were nicked and dinged like it spent an hour in a cement mixer, so I deburred and polished it and bullnosed the leading edges with a disk sander and DA sander. I deburred the block inside and out, then took it to my engine shop. The block was decked 0.010 to square it up (.003" unsquare to the crank on one bank), then torque-plate honed. This alone will improve power and mileage, as the stock hone was obviously not done with torque plates. Torque plates reproduce bore distortion resulting from bolt tension when the heads are on. A few passes of the sunnen hone revealed dimples, or low spots in the bores due to the bolt load. About 15 strokes in each bore were needed to make them clean and round, which added .001-.0015 to the bore diameter. This will increase piston clearance and require a file-fit ring set, but otherwise won't hurt anything.

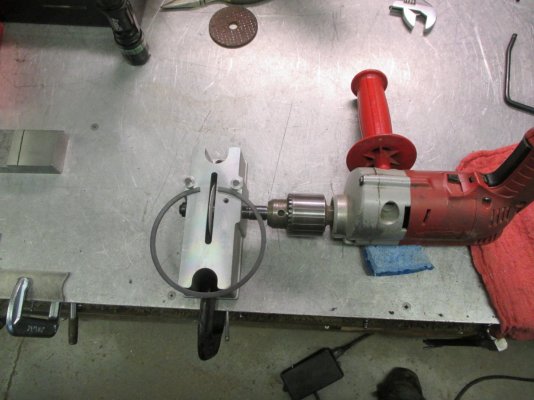

My shop supplied a Sealed Power 4.250 +.005 ring set, which needed a lot of material ground off. I got tired of spinning the ring filer by hand, so I turned it's shaft down until I could get it in a drill. I set the top rings at .018" and the second at .010. I soon discovered that the stock pistons have a shallow oil ring groove for low tension rings, but the ring set came with conventional Mk4 style oil rings. I got the right oil ring set from Total Seal for another $76.

Everything went right together after that, with ARP rod nuts on stock rod bolts. The pistons measured .014-.015 below deck, so they were a full .025 below before the deck was cut. I am surprised by that. That gap is dead space that can't be scavenged, which hurts mileage and increases emissions, so why would the OEM do it? To reduce compression? They should know better. I will be doing some cutting and polishing on the chambers that will increase chamber volume, so the deck cut will help bring back any lost compression.

For a cam, I had my eye on a Comp Cams XR258HR for a long time now. It's pretty mild, but my truck is used almost entirely for towing race trailers. So I ordered one on the website because it said they would be in stock in 2 weeks. Then I got an email saying they are really out of stock for 3-6 months due to a nationwide cam core shortage. Oh well, $380 order cancelled.

For a better solution I sent the stock cam up to Delta Cam grinding in Washington state. It came back today, 10 days and $135 later. They reground it to the more aggressive Comp XR profile, but with some custom twists. The intake now has 206° duration at .050 with .510 valve lift, the exhaust 210° with .522 lift. I requested a lobe separation angle of 112° to go between the standard performance angle of 110, and the typical 'computer controlled' angle of 114. It was also ground with 4° advance built in (stock is 6° retarded, which IS retarded). Regrinding reduced the base circle diameter by about .050, which may require custom pushrods, but that's no problem. It's also getting a Comp 3149KT timing set, 911 valve springs, 1411 rocker arms, 4514 rocker studs, and 4779 spring locator cups that eliminate the rotators.

There is a ton of other stuff to figure out. I want to add better injectors and a firewall mounted fuel regulator, and maybe a bigger throttle body. I'm adding headers and I have some big ideas to improve the intake manifold, so it will no doubt need a tune. I may need the 0411 ecm swap too. I will be reading and asking you guys for tips and links, and post some pics the build so far tomorrow.