Hamps

I'm Awesome

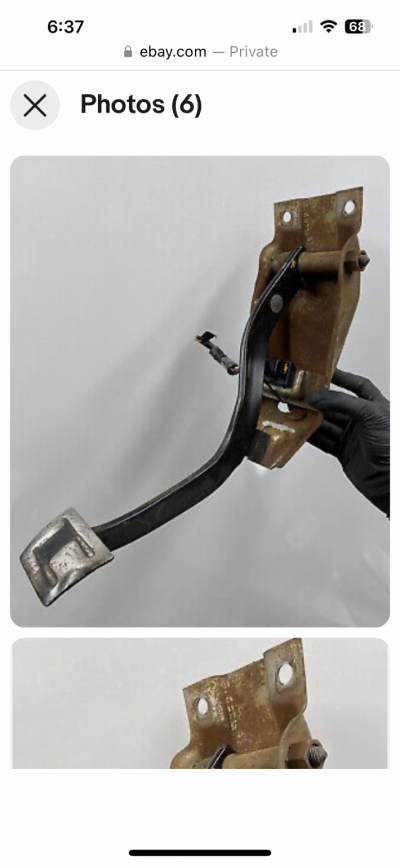

I used a wilwood .0750 aftermarket slave and it lined up perfectly with the factory bolts but had to fab a union to go to the threads. Threaded slave to clutch pedal push rod. Ram internal throw out bearing. Shifts real nice.

www.summitracing.com

www.summitracing.com

Mounts on an angle but the holes line up perfectly. The reservoir is remote mount. Did extended bleed line and everything works extremely well. Short pedal and excellent shifting even on a Sm465 pig.

Wilwood Disc Brakes 260-10373 Wilwood Compact Remote Flange Mount Master Cylinders | Summit Racing

Free Shipping - Wilwood Compact Remote Flange Mount Master Cylinders with qualifying orders of $109. Shop Master Cylinders at Summit Racing.

xc_hide_links_from_guests_guests_error_hide_media

Mounts on an angle but the holes line up perfectly. The reservoir is remote mount. Did extended bleed line and everything works extremely well. Short pedal and excellent shifting even on a Sm465 pig.