Good job so far, if you have any questions don’t hesitate to ask. I just got done setting up a 14 bolt and finishing up an 8.25”. Not an expert by any means but I have set up gears in half a dozen trucks and Jeeps.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My second 89 Shortbox project

- Thread starter 89GMCJOHN

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Doh! Now that that bearing is on you can't put a shim behind it. My pinion was too shallow, so I had to cut my bearing back off and buy two more bearings. One bearing got emory'd out on the inner race so I could put it on and take it off repeatedly as I measured for the shim. The other was the bearing that got final-installed. The downside is that if your bearings are from different lots they're more likely to have different tolerances.

89GMCJOHN

I'm Awesome

Night 2 lol ....have had it in and out probably 4-6 times so far ....I'm at .012 backlash currently so sneaking up on specd .008-.009... tomorrow I should have it dialed in....everyone has said your going to have to put it in and out several times which I'm finding to be true lol....

89GMCJOHN

I'm Awesome

Current patterns  drive bad on the toe , coast ok .....

drive bad on the toe , coast ok .....

SNCTMPL sent you a message ......

You must be registered for see images attach

You must be registered for see images attach

Here’s a few things to look at.

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

89GMCJOHN

I'm Awesome

Very informative ...thanks so much for looking this all up for me .....pictures are worth a thousand words .......simply stated pinion is in too deep ....will adjust accordingly - less shims. I should have it dialed in tomorrow finally. Ive been in and out about 10 times now lol..... An interesting tidbit I have run across in several articles I have read mentions it is better to have your drive side dialed in and your coast side a lil off than vice versa.

You must be registered for see images attach

89GMCJOHN

I'm Awesome

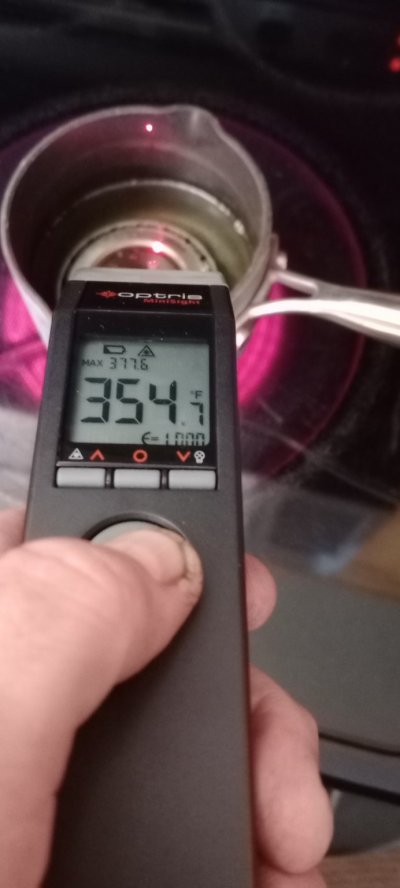

Got a good pattern today finally ...pinion way too deep .. needed an .037 under the pinion head....I caved and bought 2 pinion bearings and made a test fit bearing for multiple tries....boy thats no joke cutting through one of those bearings lol.....ran out of time -kids +but confident I will have it buttoned up next session.....thanks for all the help.....few pics with methods and part numbers....1989 2wd pinion bearing p/n in pic ....heated it to 350 degrees in oil and it dropped right on the pinion.....

Attachments

Last edited:

Similar threads

- Replies

- 6

- Views

- 246

- Replies

- 1

- Views

- 728