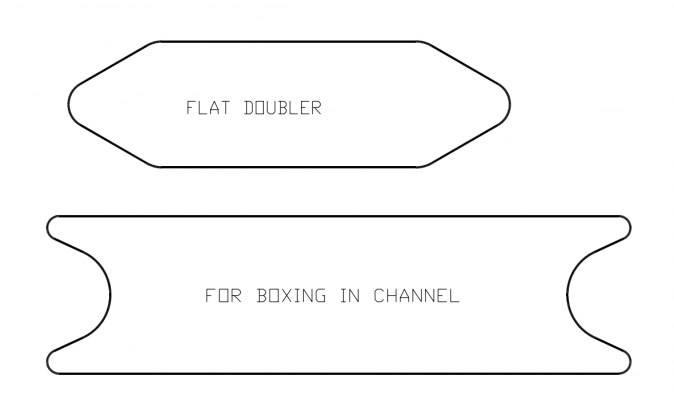

I think Hipster summed it up pretty well but I thought I'd add my two cents worth. I've been welding and training welders for almost 30 years. There's a lot of BS in the world of welding that is not backed by any science or testing. If I had a nickel for everytime a welder has told me "It'll hold" while looking at a crappy weld, I'd be a rich man. Since the frame is flexing constantly you need to be worried about two things. One, stopping that crack. Cracks can propagate quickly through steel that is flexing and or vibrating. Drilling a hole at the end of it will stop it as long as you get the end of it. which is usually past the end that you can see (that's why we have mag particle testing). The second thing is to not create stress concentrations with your repair. Putting a rectangular doubler over the repair will create stress concentrations perpendicular to the bending moment on the frame at the toe of the two end welds. To get around this you need to taper the ends of the flatbar (think a rectangle with a rounded triangle on each end). If you want to box it in with a piece of flatbar you need to do something similar with the ends I am not saying you should or should not box it in, that is up to you. I will try to add a picture. To sum it up, I would repair it by grinding all the rust out, drilling a hole at the end of the crack, maybe a half inch hole to make sure you get the crack, vee out the length of the crack and weld it. If you don't vee out the crack, you might as well not even weld it because it will fail. You might need to put a small backing plate behind it so you don't burn through. Then I would put a doubler plate over the top, making sure that it terminates on good solid steel on both ends. This is not rocket science but it does require that you be fastidious about cleaning the parent material and getting good penetrating welds. I would probably go past the first trany support bolt and re-drill that hole. Like Hipster said, I would use material the same or similar thickness of the frame. A36 steel is fine. This is like painting, it's all about the prep. I would probably pay someone to do it. This is out of position welding and is more challenging to do . Especially for a beginner. I wish you the best on this repair.