chubbusket

Newbie

I'm working on improving my 97 K2500's electrical capacity. I used this truck for plowing for the first time last year so I bought an Optima Deep-Cycle battery and ran 0awg wire for everything. The battery did well but it had a hard time keeping up with the constant hard draw from the plow. When I started the season I had installed a high-output alternator but I am fairly certain that the AGM Optima battery killed the voltage regulator in it. I've now read that the AGM battery does not accept voltage as readily as other batteries so my best guess is that when the truck wasn't using all of the power it had nowhere else to go and toasted the alternator. I asked the alternator manufacturer and they said it should be compatable with AGM batteries. Anyway, the alternator only lasted all of about 100 miles and it stopped charging. I had it replaced under warranty but then I put the old alternator back on the truck to get through the plowing season. So now I have a new, unused HO alternator. So here is my plan for what to do this season:

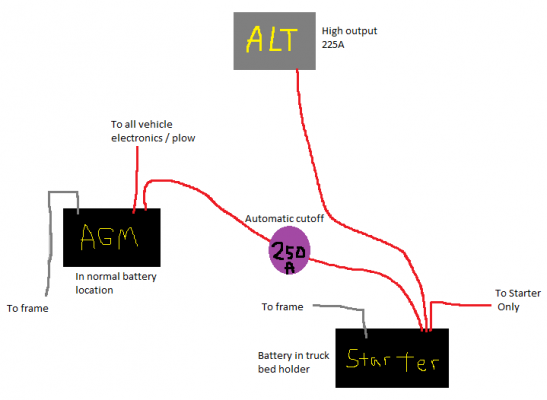

I want to install a second battery to use in parallel, a regular lead-acid one. Since the second battery location in the truck is already taken up by my plow hydraulic pump, I am going to have to put the new battery in the truck bed in a new box. Since I am mixing battery types, I read that those batteries could discharge each other so I am planning on getting an automatic battery disconnect that will be hooked up between the two batteries to take away the connection when the voltage in the system drops below a certain amount. And that way the starter battery will always have voltage to start the truck even if I use my other accessories too much with the engine shut down. And I would like to install the high output alternator again. If I hook it directly to the normal lead-acid battery I think this would give the voltage a place to go even if the AGM battery won't accept voltage as fast as the alternator wants, right? Anyway, I made a diagram of what I am thinking which I attached. I'm not an expert in this by any means but I think this setup will do what I want. Thanks for any feedback you have to offer.

I want to install a second battery to use in parallel, a regular lead-acid one. Since the second battery location in the truck is already taken up by my plow hydraulic pump, I am going to have to put the new battery in the truck bed in a new box. Since I am mixing battery types, I read that those batteries could discharge each other so I am planning on getting an automatic battery disconnect that will be hooked up between the two batteries to take away the connection when the voltage in the system drops below a certain amount. And that way the starter battery will always have voltage to start the truck even if I use my other accessories too much with the engine shut down. And I would like to install the high output alternator again. If I hook it directly to the normal lead-acid battery I think this would give the voltage a place to go even if the AGM battery won't accept voltage as fast as the alternator wants, right? Anyway, I made a diagram of what I am thinking which I attached. I'm not an expert in this by any means but I think this setup will do what I want. Thanks for any feedback you have to offer.