Supercharged111

Truly Awesome

- Joined

- Aug 20, 2015

- Messages

- 12,717

- Reaction score

- 15,529

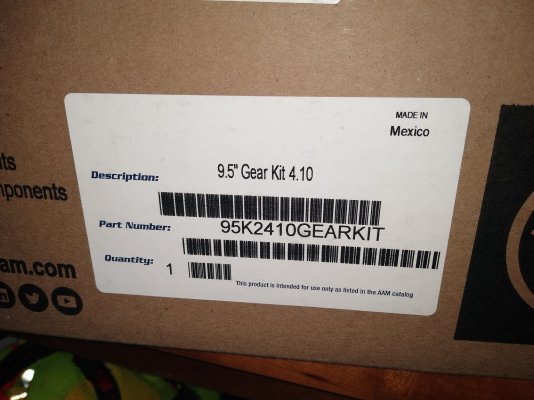

These are hybrid axles, similar to the 9.5" 14 bolt 6 lug of the GMT400 trucks.

The carrier is 9.5" "14 bolt", but the axle tubes are closer to the 10 bolt? I think that's what I read. And the cover has 12 bolts, so that's what the name that's been adopted: 9.5" 12 bolt.

So it'll hold the power, but not the weight of hauling heavy?