You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

99 L29 454 build

- Thread starter Scottm

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

I recently jumped into the gen 6 game by buying a used long block for my wife’s Chevelle. I was told of compression issues before purchase and upon tear down it seams to have gotten VERY HOT. Oil very black, valve seals baked/swollen/burnt/crispy, oil ring marks stained into cylinders, cam bearings literally melted and dripped down into motor, exhaust valve seats falling out, exhaust valve bent, and almost none of the valves sealing in heads, rings broken, and piston slightly melted. So the block and heads are at machine shop. Block getting cleaned, decked .020(stock assembly was like .025 in the hole like you found out), bored and honed to 4.310, and mains checked. Heads are getting cleaned and decked to flat. I already had a used set of SRP flat tops and some Chinese H beams that I’ll put in. I’ll put new exhaust seats in and valve job all the holes and grind the valves. As you also found out, camshaft choices are slim. I have been looking at a clay smith cam in stock at summit for $399(!!!). It’s 229/235 at .050, .600/.559 lift and 107 lobe separation. The rest will be performer rpm manifold, headers, carb. The usual stuff. I know the cam might be a little much but again it’s not going in a truck, I can afford to lose a few foot pounds down low. My quick math put me above 9.5 to 1 compression, more accurate numbers to follow.

Good points Bu, thanks. If your engine got that hot, be sure to magnaflux everything.

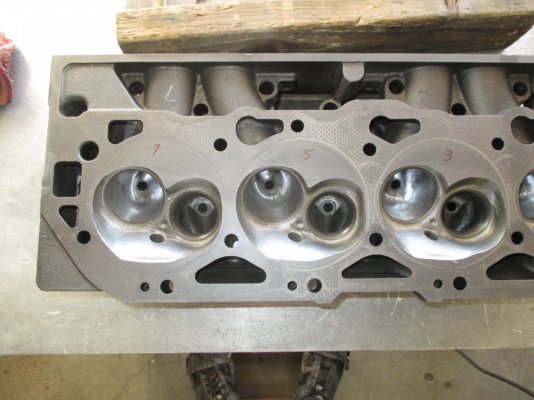

I have gotten good work done on the heads. All chambers are now equal at 105cc. With an .030 gasket, comp should be about 9.2. The exhausts measured 80-81cc before, and were quick to even up at 86cc after. Intakes are more complicated. Each head has two 'short' runners, cylinders 3 and 7 in the first pic, and two 'long' runners, cyls 1 and 5. Stock, the short ones measured 229cc, and the long measured 234cc. But the short runners are also the 'bad' ports. The long 'good' ports dump the incoming air straight down into the cylinder, but the bad ports slam the air into the cylinder wall, so airflow is less in the short ports.

David Vizard's bbc book says you can fix two problems with one move. The wire in the second pic is pointing to the outside wall of the number 7 intake. By grinding away some material on this wall as it approaches the valve pocket, air flow along this wall is enhanced, which increases flow and also makes the flow hook away from the cylinder wall and toward the middle of the cylinder. After grinding, the shorts measured 238cc, and the long measure 240cc. I am scheduled for the flow bench late next week, so the theory will be tested.

Also I have used drugstore 50/50 alcohol and water for volume testing, but a few days ago I knocked over my only bottle. I tried this cheapo paint thinner that was laying around, and I like it better! It makes removing grease residue on the valves and plastic cover after measuring easier too.

I have gotten good work done on the heads. All chambers are now equal at 105cc. With an .030 gasket, comp should be about 9.2. The exhausts measured 80-81cc before, and were quick to even up at 86cc after. Intakes are more complicated. Each head has two 'short' runners, cylinders 3 and 7 in the first pic, and two 'long' runners, cyls 1 and 5. Stock, the short ones measured 229cc, and the long measured 234cc. But the short runners are also the 'bad' ports. The long 'good' ports dump the incoming air straight down into the cylinder, but the bad ports slam the air into the cylinder wall, so airflow is less in the short ports.

David Vizard's bbc book says you can fix two problems with one move. The wire in the second pic is pointing to the outside wall of the number 7 intake. By grinding away some material on this wall as it approaches the valve pocket, air flow along this wall is enhanced, which increases flow and also makes the flow hook away from the cylinder wall and toward the middle of the cylinder. After grinding, the shorts measured 238cc, and the long measure 240cc. I am scheduled for the flow bench late next week, so the theory will be tested.

Also I have used drugstore 50/50 alcohol and water for volume testing, but a few days ago I knocked over my only bottle. I tried this cheapo paint thinner that was laying around, and I like it better! It makes removing grease residue on the valves and plastic cover after measuring easier too.

Attachments

The heads are done, so today I started playing with the manifold. It is definitely a bad design. There is almost 1/4 inch of mismatch at the top of the manifold ports. But the good news is the extra material is easy to grind away, so it is easy to make it match perfectly. I was bummed about the stock manifold before today, thinking there was no way to get decent power out of it, but this should make a big improvement. I did grind through at a thin spot, so I clamped a piece of copper sheet metal on the inside, and welded it up on the outside. Next time I will weld fill in the low spots on the outside before I start grinding.

Attachments

Cool, good to have a reference. I think these heads can beat that though. I did a pair of 195cc AFR smallblock heads that flowed 280 cfm with about the same size intake valve, but these L29 heads are 240cc runners. I predict close to 300cfm. Then I will attach the stock manifold and see how bad it kills my dream. One side of the manifold is unmodified, so I can see the before/after on manifold work. In case both numbers with the stock manifold suck, I'm bringing a Victor Jr oval port to find the real potential. Friday at 9 am, fingers crossed!

Similar threads

- Replies

- 3

- Views

- 620

- Replies

- 5

- Views

- 1K

- Replies

- 8

- Views

- 2K

- Replies

- 6

- Views

- 2K

Latest posts

-

-

-

-

Breaking yard etiquette. Discussion debate personal views please

- Latest: Erik the Awful

-

Staff online

-

kennythewelderOfficially Retired, B31-3 (6-G) certified welder.

Members online

- 0xDEADBEEF

- Erik the Awful

- PM18S4

- Road Trip

- Crawlblind

- Thebluebitch96

- Bandit4Life

- 454cid

- nickc2500

- 1998_K1500_Sub

- Keeper

- vince72

- 77Eltigre

- caw_86

- PolarBear

- Aidan Kesler

- shamusshanahan

- 1 slow 84 chevy

- mrzabel08

- Drunkcanuk

- skylark

- PlayingWithTBI

- alexander1244

- 618 Syndicate

- snowboardfan03

- evillarreal93

- Orpedcrow

- k00laid83

- britnaymartinez12

- Pepsikid628

- highriseZ71

- K3V0

- truedual93

- RhettR7707

- Supercharged111

- fancyTBI

- jgreen16

- ctvaughn

- 90sprobs

- ldaggerl

- Green96

- Yatesbriar12

- 99yk

- Curtis21

- FIREBALL 94

- OutlawDrifter

- kennythewelder

- SierraK2500

- tojorazz

- Danimal08

Total: 1,461 (members: 64, guests: 1,397)