That is a mechanical problem.

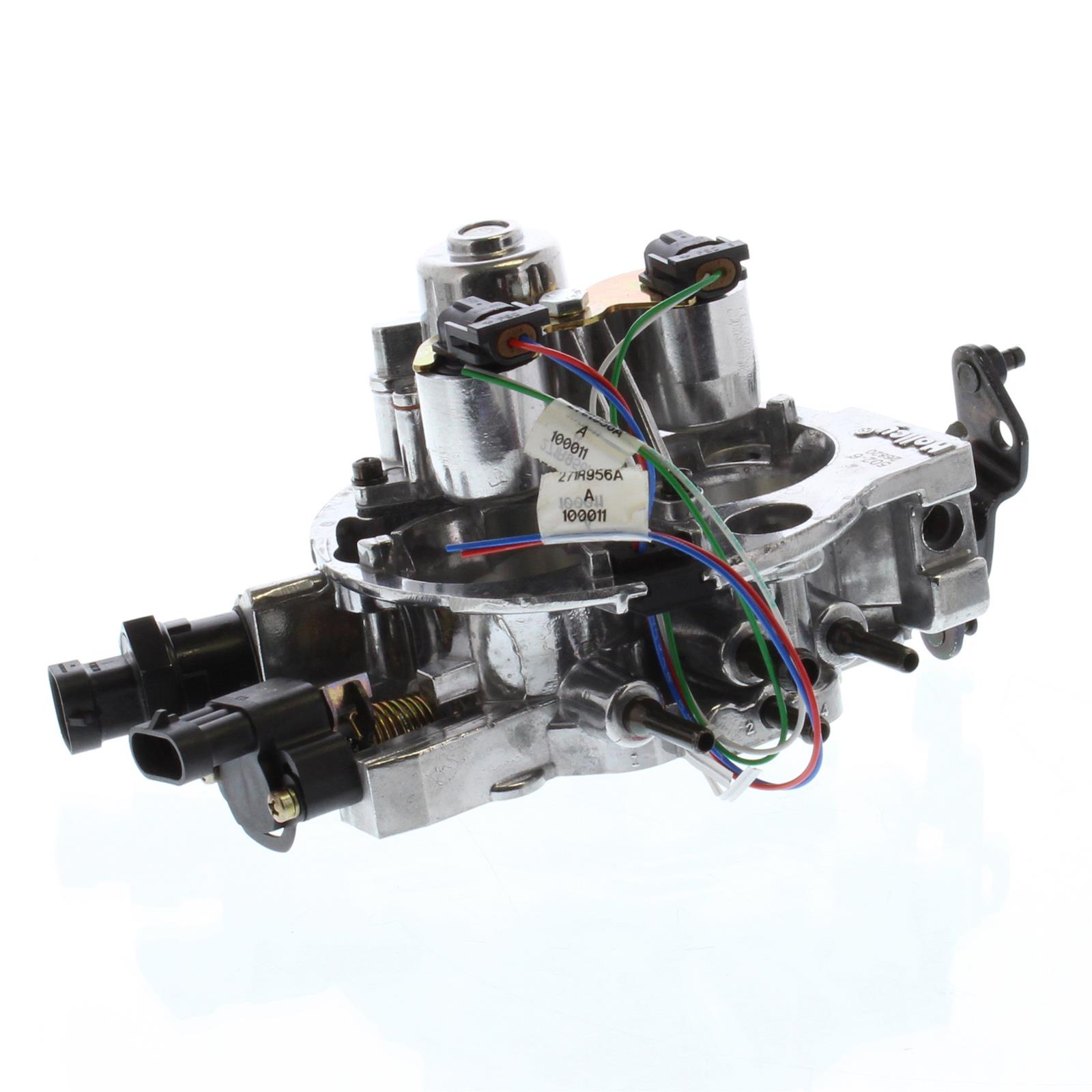

Worn throttle shaft, cruded up throttle bores, throttle plates sticking when hot.

High hot idle because the throttle wont close.

Pulling air through the worn throttle shaft bushings when at idle.

Bad base gasket. Etc.

Rebuild the tbi and replace all of the vacuum hoses.

Clean the EGR and all of its ports and passeges.

I know better educated guys than me will show up but I just dont believe that a 89 ECM has any way to make the throttle stick open.

I think you have a entirely mechanical set of issues.

Stuck, worn throttle likage, bad cables. etc..

Dont be so quick to discount the guy who mentioned bad motor mounts either.

Back in the early 70s, The biggest recall in history was from motor mounts.

This is why we have "caged mounts"

They are designed to hold the engine in place if the mount seperates.

If you break an uncaged mount on anything before about 1970 or so the torque of the engine will rotate it and pull the throttle wide open.

It pulls the pedal right from under your foot and slams it on the floor and chucks you in the back seat.

The only thing you can do is try to shut it off.

Hard to do when you are in the back seat.

Worn throttle shaft, cruded up throttle bores, throttle plates sticking when hot.

High hot idle because the throttle wont close.

Pulling air through the worn throttle shaft bushings when at idle.

Bad base gasket. Etc.

Rebuild the tbi and replace all of the vacuum hoses.

Clean the EGR and all of its ports and passeges.

I know better educated guys than me will show up but I just dont believe that a 89 ECM has any way to make the throttle stick open.

I think you have a entirely mechanical set of issues.

Stuck, worn throttle likage, bad cables. etc..

Dont be so quick to discount the guy who mentioned bad motor mounts either.

Back in the early 70s, The biggest recall in history was from motor mounts.

This is why we have "caged mounts"

They are designed to hold the engine in place if the mount seperates.

If you break an uncaged mount on anything before about 1970 or so the torque of the engine will rotate it and pull the throttle wide open.

It pulls the pedal right from under your foot and slams it on the floor and chucks you in the back seat.

The only thing you can do is try to shut it off.

Hard to do when you are in the back seat.