Supercharged111

Truly Awesome

- Joined

- Aug 20, 2015

- Messages

- 12,705

- Reaction score

- 15,503

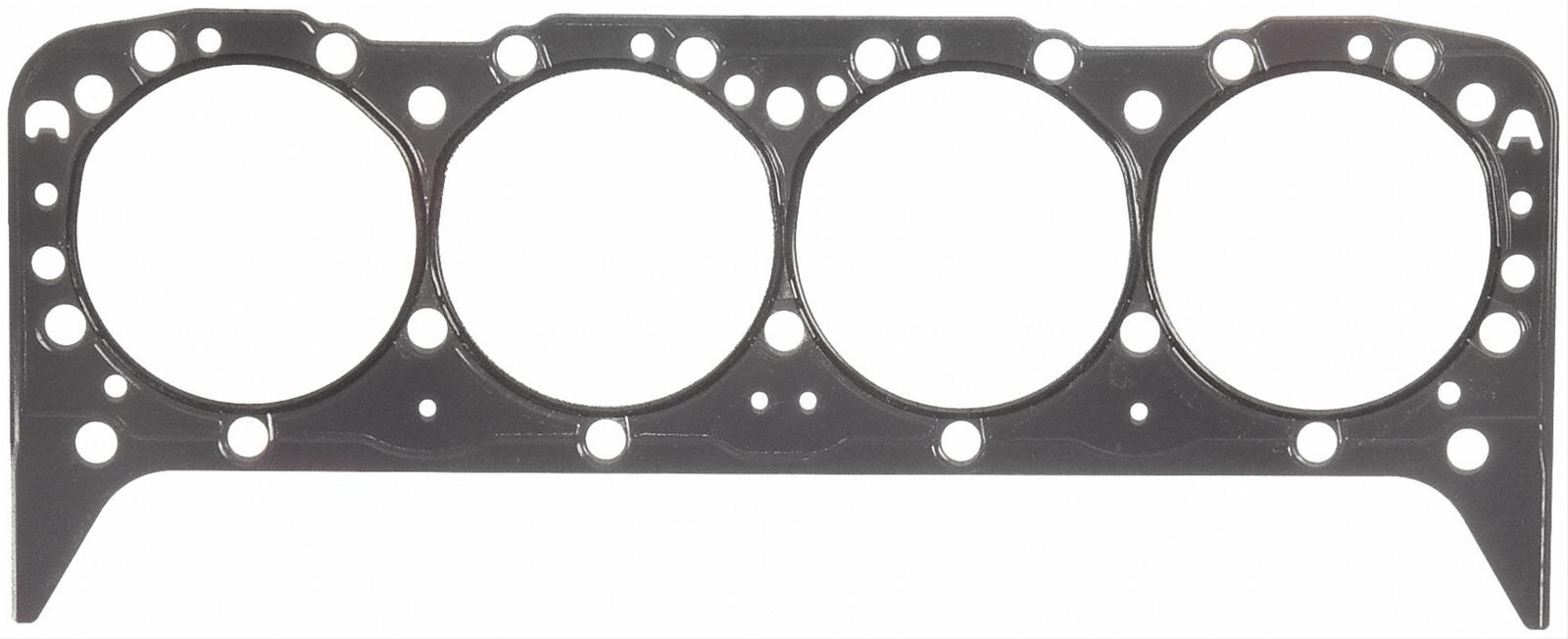

Felpro changed the coating recently from black to clear but the last set was definately coated when I ran my finger across them. Looks like they are 0.015" compressed now too. Some people copper coat them, but if the deck surface and head face is clean, not badly pitted and straight, I bolt them down and go. Worth a slight bump in compression.

Fel-Pro 1094 Fel-Pro Performance Head Gaskets | Summit Racing

Free Shipping - Fel-Pro Performance Head Gaskets with qualifying orders of $109. Shop Head Gaskets at Summit Racing.www.summitracing.com

Thank you!