Googling??? Why are you using Google?JB6? My suburban is a '92 K1500 4wd. After Googling, I would say yes...

LOOK at the SPID decal in the glovebox. If the VIN number on the decal matches the VIN on your truck, and if it says "JB6", the truck was built with JB6 brakes

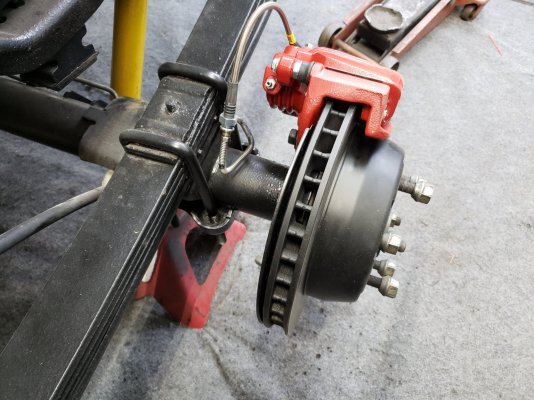

JB6 = Low-drag calipers in front with 1.25" thick rotors, 11.x Duo-Servo drums in the rear. Big booster, big step-bore "Quick Take-Up" master cylinder. Not a bad system at all. That's what I upgraded my '88 K1500 to, from JN3.

JB5 would be the same front brakes, same booster/master, but crappy 254mm (10") Leading/Trailing drums in back. But I don't think the Suburbans ever got the horrible 10" L/T drums.

JB7 would be even bigger, non-low-drag front brakes, and 13" rear drums. I bet you'd have to have a full-float axle for those rear drums to fit. (Not likely on a 1500, but if the right option boxes were checked, it might be possible.)

Calipers are machined to allow the square-cut seal to retract the piston more than typical. Therefore the pads don't drag on the rotor, therefore GM achieves 0.000000003 percent better fuel economy which probably also improves emissions compliance.Low drag, please explain??

The low-drag calipers require a special "Quick Take-Up" "Step-Bore" master cylinder, because they need a gush of fluid at low pressure to take up the extra pad-to-rotor clearance before braking even begins. The QTU master has three chambers instead of the usual two--there's a large-diameter low-pressure chamber at the rear of the cylinder, but the two high-pressure chambers are of normal diameter, therefore normal pedal effort. Regular master cylinders don't have the capacity for fluid movement unless the cylinder bore is huge. And if the cylinder bore is huge...the pedal effort goes way up. So if the booster fails, you'll need both feet, all your weight, and a big squirt of adrenaline to stop the truck. IF your wife or kids are driving, I hope your truck and medical insurance is paid-up.

But as I understand it, you're scrapping the low-drag calipers, so you won't need a QTU master.

Bigger brakes done correctly are not a bad thing. You're acting as a brake engineer, it's your responsibility to assure that all the parts work together, you don't upset the brake balance front-to-rear, and you don't screw up the hydraulic ratio between master cylinder and wheel cylinders (including calipers.)I was planning to take the HB and MC from the '02 2500 suburban but was already removed from this suburban before I could get to it at PNP, so I have to find another candidate...I saw the difference between the 1500 and the 2500 NBS suburban brakes and I would like the 2500 brakes on my burb if possible.

If you swap to GMT800 brakes, you'd better take everything so you still have a "matched set" of components--including the rear brakes. I don't know what if anything is different at the rear. But YOU better know.

Me? I upgraded my K1500 pickup to the brake system your 'Burban has now. I'm perfectly happy with it. So I'm a bit mystified why you feel it necessary to expend time, money, effort, and enthusiasm to upgrade to GMT800 stuff. I just hope you do it wisely, and I hope you do it because you're not satisfied with what you have, and what you have is WORKING PROPERLY. It would be a shame to find that you've upgraded the brakes only to discover that the reason you were unhappy with the existing brakes was because the rear brake hose was partially plugged, or the power booster was weak, or some other defect led you to believe your brakes were substandard when they merely needed repair.

Last edited: