Wheeze, squeeze, please, more wheeze - that's a 4 stroke!

2 strokes are simple when you break down what is happening into 4 stages.

The firing/expansion/power part - obvious.

Blowdown - which occurs toward the end of the expansion stroke when the exhaust port is opened (either in the cylinder uncovered by the piston or some other mechanical valving eg, poppet valves in the head, etc). The purpose of blowdown is to lower the cylinder pressure to that of the transfer ports.

Gas exchange which begins when the transfer ports open and the incoming air and/or mixture is introduced to the cylinder in a manner that will flush out the remaining exhaust gas products - the pressure of which fell to that of the transfer ports during blowdown.

When the transfer and exhaust ports close and the piston is again rising, compression begins. Rinse repeat.

There are three scavenge models: Schnurle (loop), crossflow (deflector piston), and uniflow (from one end of the cylinder to the other). They all have their merits and demerits.

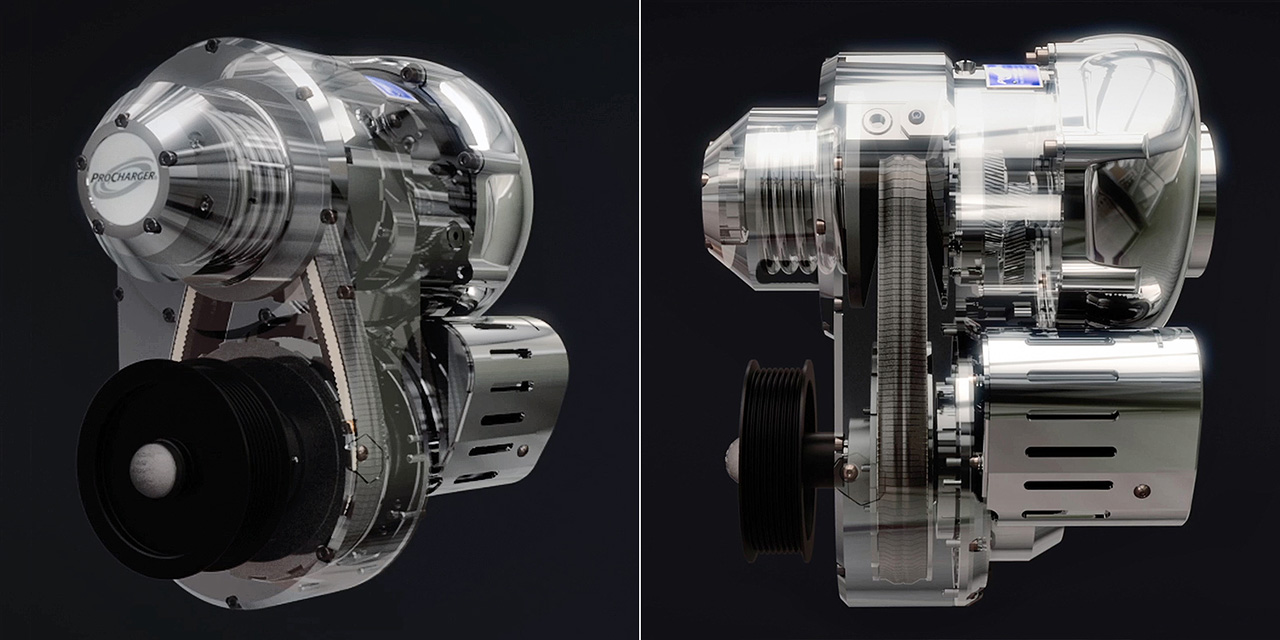

And two methods of air supply - crankcase scavenged (where the crankcase is merely a low pressure pump) and externally charged (mechanically driven blower and in some cases turbochargers).

The 2Ts we encounter can be defined by their BMEP which is largely dependent on their exhaust type.

4 bar: hand held, simple exhaust.

8 bar: outboards and the likes that employ 'compact branch manifolds'.

12 bar: high performance engines eg, sleds that use expansion chambers. (how expansion chambers work is mind bending!).

There's also the very big 'cathedral' 2T diesels that power huge ships and turn at 80-100 rpm. They have thermal efficiency circa 50%. Not much can touch that.

2T has been neglected. The best piston engines up until WW2 were aero-engines. 4 valve/cylinder and forced induction (supercharged) they were left for dead by the gas turbine/jet engine. If the gas turbine/jet engine hadn't killed them the 2T would have. The Rolls Royce Crecy and later, Napier's Nomad, had the 4T beat - but all the development went into gas turbine/jet engines.

At the same time, auto manufacturers returned to car production with the same engines as they'd used before WW2 (side valve units often enough) and it wasn't until the 1980s that what was common in aero engines (4 valve heads and forced induction) finally appeared for road use and another 30 years for it become common. 60 years after the aero industry would have abandoned it anyway for 2T had the gas turbine/jet engine not prevailed.

When you compare how much development the 4t has had for road use, the 2T has had next to nothing. Apart from the 'cathedral' diesels, only where the 2T's virtue of extreme simplicity/low first cost or light weight (or both) has been a necessity (hand held tools, sleds, light boats) have they had any attention.

In todays world - as was said back in the 1960s - ''the 2T will have to be revisited when NOx emissions become problematic'' (because the same power can be had with half the NOx creating cylinder pressure) - they could be of use.

All of that is probably more than you wanted to know!

Bottom line: a 4T is a complex engine that is easily understood. The 2T is a simple engine that is extremely nuanced in its operation. There's an expression in engine design circles: 'give the 2T engine to the 4T guy and watch him **** it up'. The Crecy and Nomad show there is still huge potential in the 2T - particularly in harnessing the energy in the exhaust gas that a 4T wastefully throws down the pipe.