DennisT

I'm Awesome

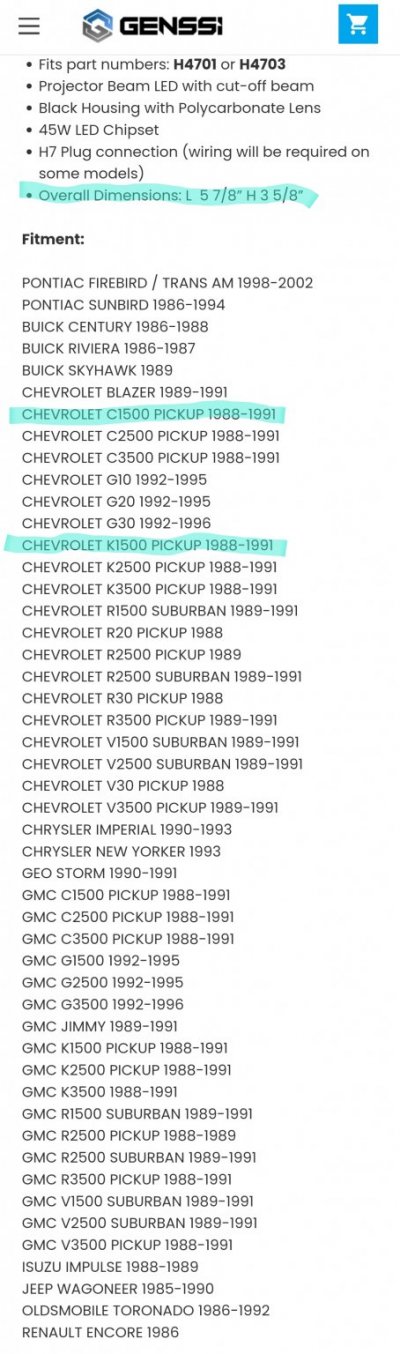

This is an extension of my post of Dec. 29th., on '89 glass Quad need adj. info and stuck screws. That thread became multi-layered but very helpful to me. As I continue to work my way through the process of getting a set of these old mini 1988/89 glass sealed beams installed on my 1996 GMC K1500, I thought it best to focus on what I now think is the, "Achilles Heel," of these d$*&nd things - the Adjusters. Hence, more of a single-subject thread. All the other conversion details appear straight forward, and, again, yes, I'll be installing HD direct 12V wiring and 4HI. I scrounged a set of these quad lamps and mounting brackets, complete, from wrecking yard. Later got a single bracket/lamp assembly. So I have a set-and-a-half to work from. ALL of them have adjuster problems, even though I've been gentle with them. It took me a while and help from this forum to realize they only adjust from the top; not from the front torx screws that square-lock into the bucket edges. To accomplish top adjusting, GM in their wisdom created a right-angle drive that resides to the rear of the screw that appears in the front. Most of you voice trouble with these little gear boxes. Some day I'll get a spare gear box and open it up to see what makes it tick. One of the better suggestions in my old thread was from Frank Enstein, who urged me to disassemble the entire unit. When I did, having removed tension on the screws, I found I could turn the adjuster on top for a couple of them. However, doing that also turned the screw facing out front, which, when captured by the square cut-out in the bucket would not have been able to move at all, as it would be, "captured." Worst of all, turning the top vertical screw, turns the horizontal screw......BUT, the horizontal screw does NOT move in or out of the gear box. So in it's present state, it is incapable of adjusting the headlight! So I think something inside the box is broken. I'm anxious to get my hands on one of these adjusters that actually works properly. I've never had that experience. I'm going to attempt to post several photos in the hope all this will help others in the future. Meanwhile, as I'm still am an

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

, "adjuster Novice," perhaps some of you can help perfect this humble document/thread into something useful long term in this forum. Thanks for your patience, Dennis