Still trying to get some insight on this, when I feel like I’ve narrowed it down, I’m just back to square one. Sorry for the long post.

Did a lt4 hot cam, not sure if that will cause the misfire, tuned ecm from black bear for it.

97 5.7l , random misfire, shakes every few seconds or so at idle. First start of the day it fires right up, will crank and crank and crank unless I crack the throttle just a little bit any start after that. Even 3 seconds of running on the first start of the day.

Now this is where I’m stuck at, when i unplug the MAP sensor truck fires right up no problem. I sprayed everything I could up top with brakleen for vacuum leaks, no difference in idle.

It’s showing misfires on every cylinder except 8. 2 the most, plug looks fine.

I do have a mail order tune from black bear performance. He’s very knowledgeable but hard to get a hold of. I have narrowed something down though, he just happen to get back to me and say that my tune target timing at idle should be 26-28*. On my scanner I’m looking at 36* timing, cam retard at 0. Now I do not know how to change the timing without changing the retard.

Hello again Dlipp_,

Let's see, since you're driving a '97 I need to switch to the Vortec perspective, offer a few bits of info, and ask

what visibility you have regarding the live data from your VCM, in that order.

First things first. For some reason I initially got the impression that your engine bay was under TBI control. My bad

for not double checking, but by the same token the ability to access live data (and eventually tuning this yourself)

will be a lot easier in Vortec OBD2 land versus trying to set yourself up for the same capability in the OBD1-era TBI setup.

OK, normally with hard starting the first variable we need to validate is the correct fuel pressure. According to your

parts list, both the fuel pump & fuel filter have been changed out, and I'm assuming that the ground connection

were brought back to new condition while the pump was replaced. (G404?)

But what I found interesting is that by disconnecting the MAP sensor your starting issues disappear? According to

the '97 Factory Service Manual, the MAP and the TPS sensors are used to calculate fuel delivery. And *if* the VCM

detects a malfunction in the MAP circuit, it will substitute a calculated value for the MAP value so acceptable

performance is maintained:

(taken from the '97 Factory Service Manual)

You must be registered for see images attach

From reading your original post, I know that the MAP sensor has already been replaced, so

here is where Mr. Schurkey would want to know what MAP readings your VCM is reporting.

(Problem in the wiring harness, bad out of the box new sensor of dubious parentage, etc)

This would be the next logical step, but for the moment let's assume that you don't currently

have access to live data like that. Instead, let's focus on the starting behavior for right now.

If I interpreted what you wrote correctly, you are saying that the first start is always good,

but subsequent starts are long cranking affairs unless you slightly depress the gas pedal?

(With the MAP sensor connected.)

But if you disconnect the MAP sensor, the starting is always good?

Coming at this from a slightly different direction, if the timing at idle is currently at 36° at idle with

the MAP sensor connected, does it change back to the tuner's spec of 26-28° if you were to

disconnect the MAP sensor?

Q: One thing you haven't mentioned is whether or not you have a SES/CEL light illuminated at

any point? Are there any DTC codes being stored, whether or not the SES light is on?

Obviously at this point I have more questions than answers, but hopefully we can sort out what's

going on and start making some troubleshooting progress.

****

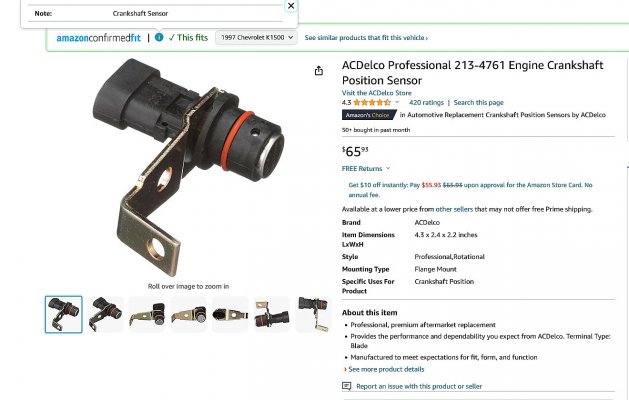

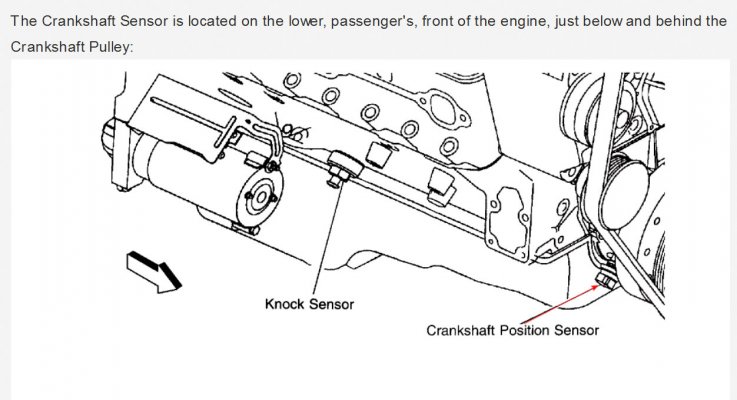

By the way, when it comes to ignition timing in Vortec-land, please keep in mind that ALL your initial

(base) timing is set by Mr. CKP, and has nothing to do with twisting the distributor housing position. (See

attachments #1 & #2 for details.)

As for the 'Cam Retard' value, if it was up to me I would rename it 'Rotor Tip to Spark Plug Wire Terminal Alignment' value.

In English, changing the Cam Retard reading will not alter when the spark plug will fire

inside the combustion chamber. On the other hand, if you get the Cam Retard far enough out of spec,

you may end up with the wrong spark plug terminal closer to the rotor tip than the correct one...and sending

sparks at the right time yet down the wrong spark wire to the wrong cylinder is obviously a sub-optimal tuning strategy.

So, please leave the Cam Retard set to 0°, and let's instead figure out why your timing isn't where

your tuner expects it to be. And no better place to start than to figure out why your engine is

starting better with the MAP disconnected.

If you reply back with the status of your DTC codes, your SES light, spark timing difference (if any) at

idle with your MAP disconnected, and what you are currently using to read data from your computer,

then maybe we can start to tighten up the problem definition.

One last thing. I'm assuming that you are running a black box VCM with a known-good custom tune from

Black Bear, and once we get all the sensors verified good that the truck will run well. IF we get all the

sensors working as advertised and the combo still refuses to run correctly, this is when it will be decision

time: Do you amass the specific tools to tune the black box yourself, or do you join the 0411 club

where there's a lot more knowledge/activity in the area of self-help custom tunes? The point is, what you are

trying to do is not impossible, but there will be a learning curve to be sure.

It's late, and that's all I got for now. More food for thought than answers to be sure, but that's

how these things get going.

Cheers --

Attachments

Last edited: